Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

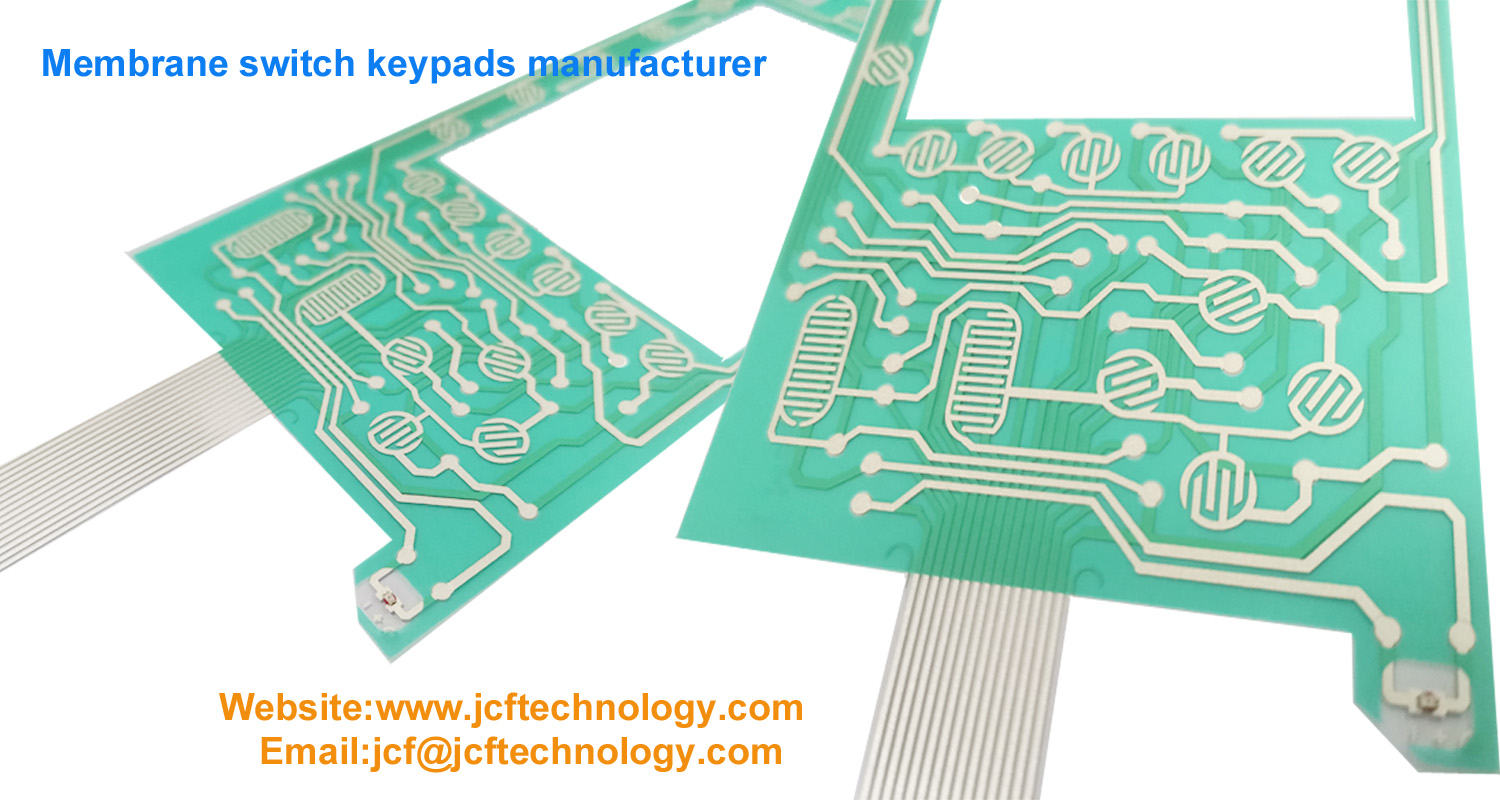

1,Open circuit and short circuit: The membrane circuit does not allow any open circuit or short circuit in the conductor.

2,Residual objects: The membrane switch printed circuit must be clean and tidy.

3,Conductor thickness membrane circuit : Generally, the thickness of conductive silver is controlled at 7-12μm, and it should be uniform and smooth.

4,Position offset of the upper and lower circuits: the allowable tolerance for the mutual offset of the center positions of the switch contacts of the upper and lower circuits is 0.2/-0.2mm.

5,Material: base sheet, silver paste, carbon ink,adhesive, adhesive, reinforcing sheet, insulation printing should meet the

requirements of the customer's drawings.

6,Shape membrane keyboard: shape, conductor jn circuit, insulation treatment, liner board combination, etc. should meet the requirements of the customer's drawings or the samples provided.

7,Defects and small holes of the conductor: According to the standard shown in the figure, one is allowed within each 50mm range.

8,Carbon ink: The carbon ink covering the silver paste circuit should ensure that the silver paste is completely covered, with a thickness of 8-10μm, and there should be no obvious leakage of the silver paste circuit.

9,Punching hole and die cut size: Punching size should not be greater than 0.2mm, and the position should be toward the side without conductors.

10,Membrane switch keypad contact points: there must be no insulating ink attached, and the insulating ink surface should be flat to avoid any defects such as bubbles or small holes that affect the insulation effect.

11,Combined state membrane keypad : The surface must not have residual material scraps, foreign matter, stains, grease attached to the surface and inside, fingerprints on the circuit.

12,Scratches: All circuits and contacts must not have cuts running through the surface and the inside. The principle of slight scratches is not to affect its impedance. The surface of carbon ink is very easy to have scratches, and the scratches are not to affect the circuit conduction as a criterion.

13,Adhesion strength: After the insulating ink is dried, put the ink surfaces against each other and press for 24 hours to ensure that the insulation does not stick to each other. After 1 minute with pressure-sensitive tape attached to it by hand without air bubbles, it will peel off quickly and no ink will fall off.

14,Bridge circuit: All membrane switch bridge circuits are in accordance with the requirements of circuit conductors, and all bridge circuit products need to pass 100% open circuit, short circuit test and insulation resistance test. Ensure that there are no open circuits, short circuits, and insulation resistance should be greater than 500MΩ

More information:www.jcftechnology.com