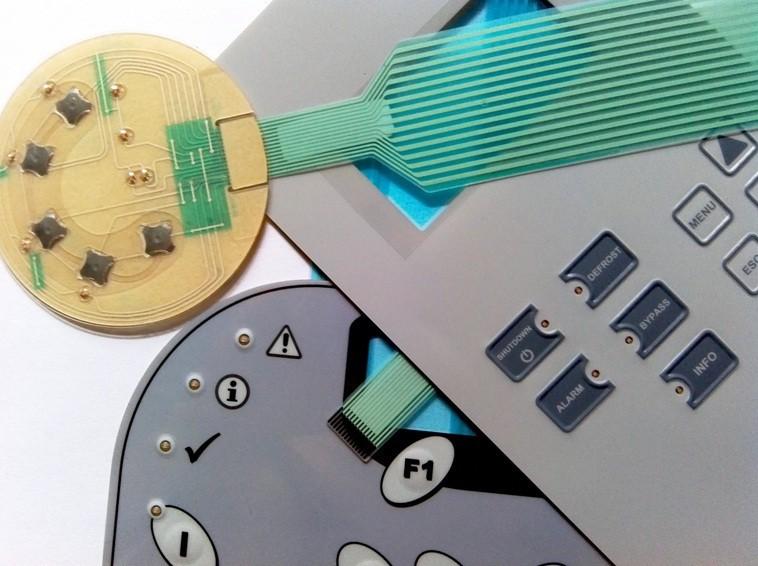

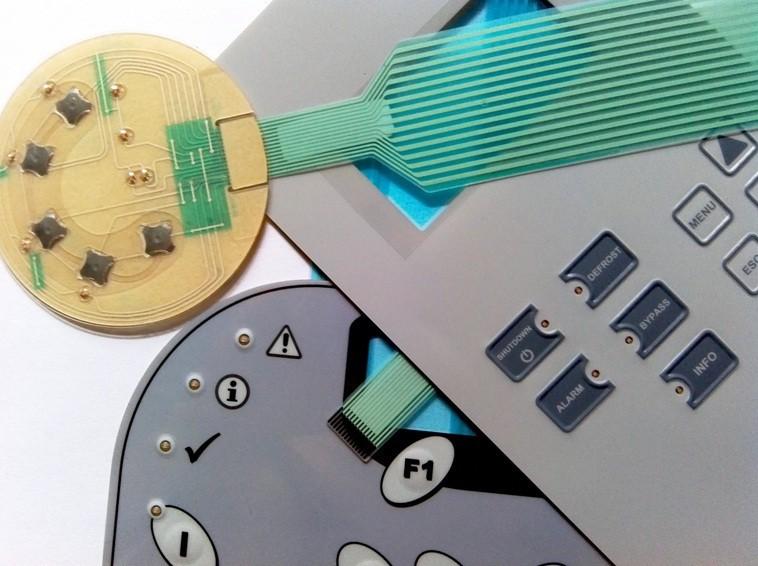

What are the die-cutting processes for membrane switch keyboards?

2021-12-07

Membrane switch keyboard Die Cutting and Finishing

Standard steel rule dies are used to cut overlays and panels less than 0.030” thick. Matched tool die sets are used to cut material over 0.030” thick. For a prototype or small quantity an industrial laser can be used to cut

membrane switch parts.However, one disadvantage of industrial lasers is that the edge of the cut will be yellow, which is not suitable for large-quantity order production.

The design and configuration of the steel rule die is so critical to the production efficiency that it will usually pay for itself in the long run. Standard specificationsare as follows:

The minimum radius on a steel rule die is .030” on the outer perimeter and.050” on interior cutouts. This is based on a standard 2pt center bevel rule.

The minimum distance cut to cut is .070”.

The die cut to printing tolerance is +/- .010”.

The maximum variation where rules butt is +/- .005”.

The tolerance for laser cut parts is:

Laser cut to dimension +/- .005”.

Laser cut to printing +/ - .010”.

The tolerance for matched tool sets is:

Dimensional +/- .002”.

Die cutting to printing +/-.010”.

More information visit:www.jcftechnology.com

#membraneswitches #membranekeypads #graphicoverlays #Lexanlable #membranecircuits #backlitmembranekeypads #LEDbacklitmembraneswitches #ELbacklitmembraneswitches

#LGFbacklitmembraneswitches #hightechcapacitivemembraneswitches #nameplates

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com