Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

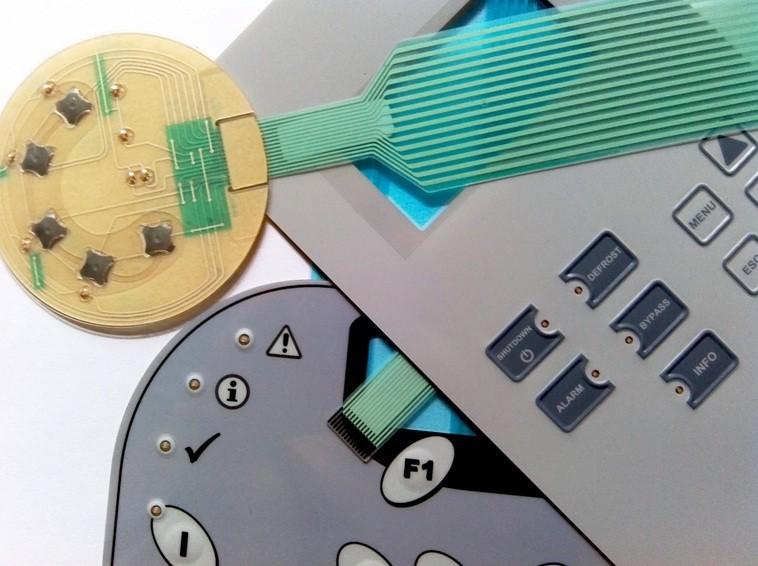

Membrane switch keypad have a wide range of applications, and quality assurance is very important. When there is a quality

failure, it will cause great difficulties to users. The faults and maintenance solutions that are prone to occur during the use of

membrane switch button are as follows:

1,Membrane switch circuit short circuit fault

If the strength of the bridging circuit in the production of membrane circuits is not enough, the insulation layer will be damaged

during use and a short circuit fault will occur. Bubbles and impurities will be generated during the printing process of the

insulating layer. If the thickness of the insulating layer (UV) is not enough or the intensity of ultraviolet light is not strong, it will

affect the insulation effect of the circuit. When the insulating layer is printed, it must be made in a very clean environment, and

the ultraviolet light must dry the film circuit immediately.

2,If the circuit button does not have a rebound function, a short circuit fault will also occur. There are two reasons for this failure:

A, Poly dome must control the temperature embossing during the production process, and the embossing will be better if the elasticity of the spherical shape is used.

B. It is very important to choose the manufacturer of the metal dome. A metal dome with poor quality will cause a rebound failure. A metal dome with a good quality has a service life of 1,000,000 times.

The membrane switch panel cannot be bent during use, and must be used on a flat surface. Once the membrane panel is bent, there will be a circuit short circuit fault.

More information visit:www.jcftechnology.com