Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

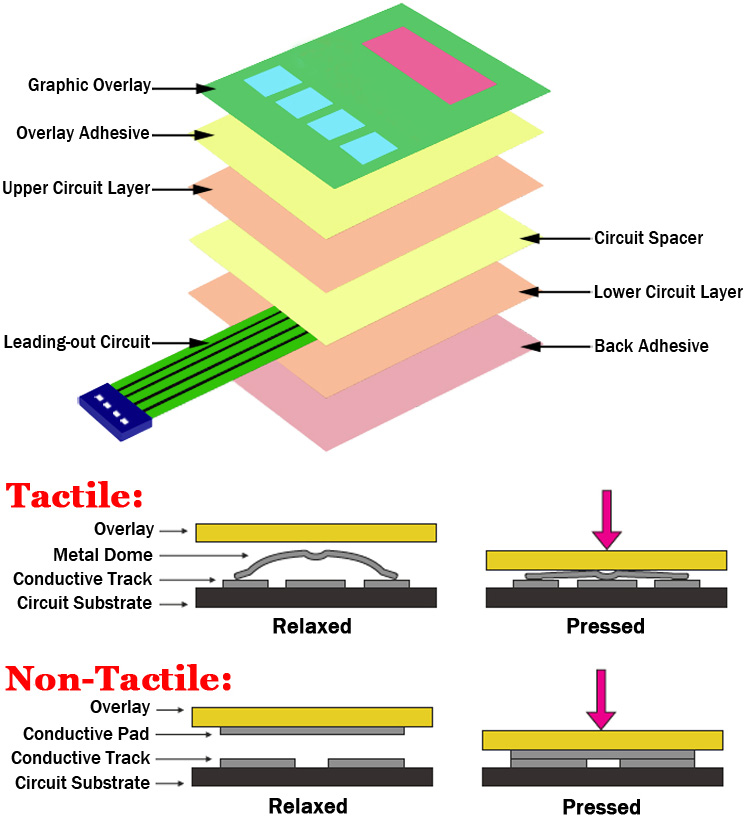

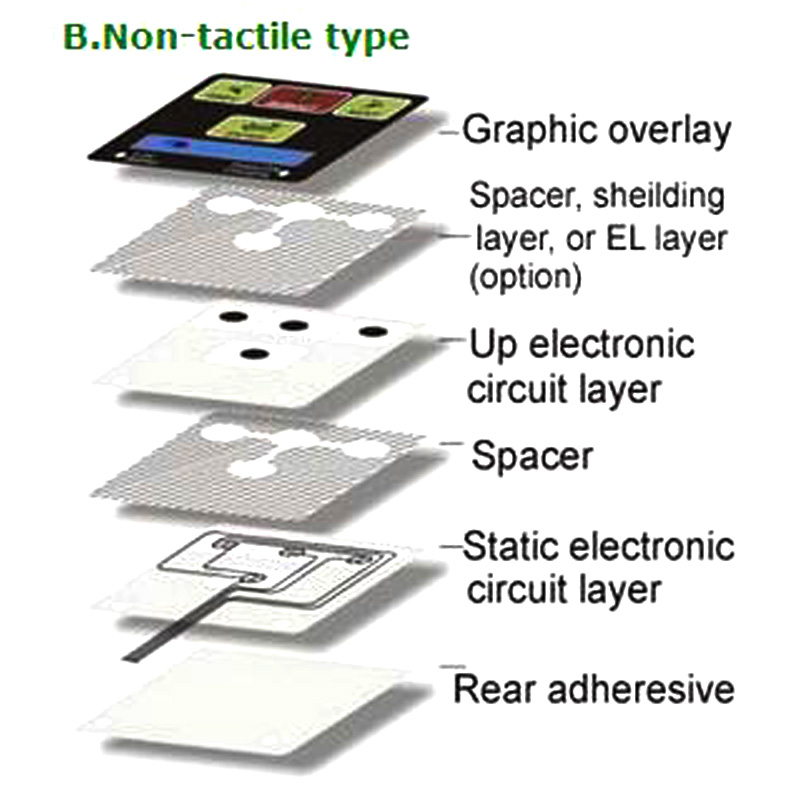

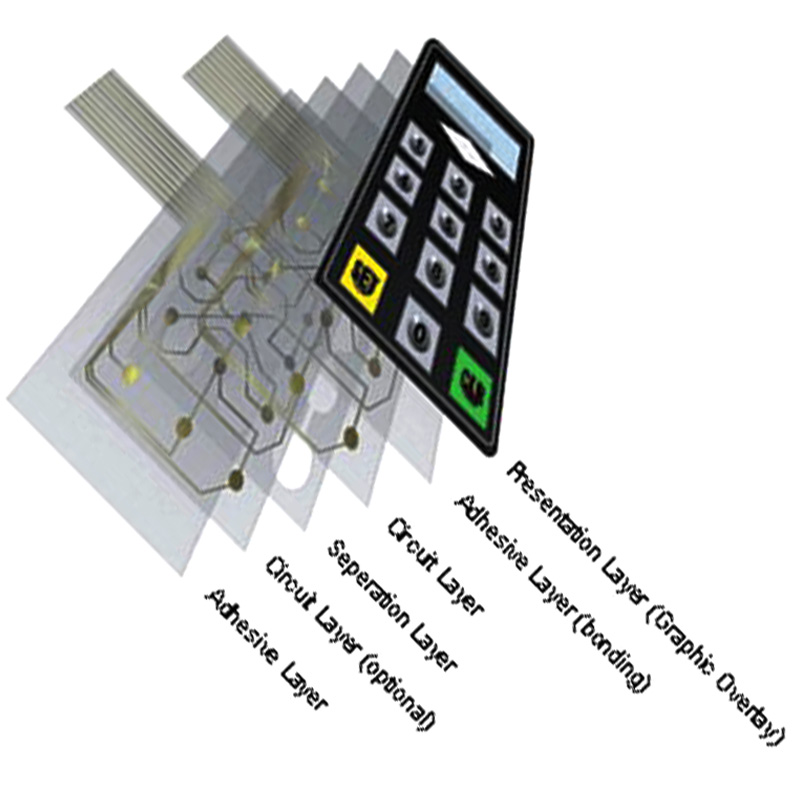

Membrane switches are structurally divided into two categories: tactile keypads and non-tactile keyboards.

Non-tactile is generally available in two configurations: flat non-tactile and embossed button Braille non-tactile. Non-tactile membrane switches do not have high requirements for finger touch, but have high requirements for sensitivity. Lightly tactile keys are turned on, and the circuit is disconnected when the keypad is not pressed. Therefore, the isolation UV point should be increased for the lower circuit button. In order to facilitate operation and improve accuracy, graphic overlays can be designed with button embossing. In recent years, many planar non-touch membrane switches have been converted to capacitive membrane switches.

Two types of Tactile Membrane Switches:

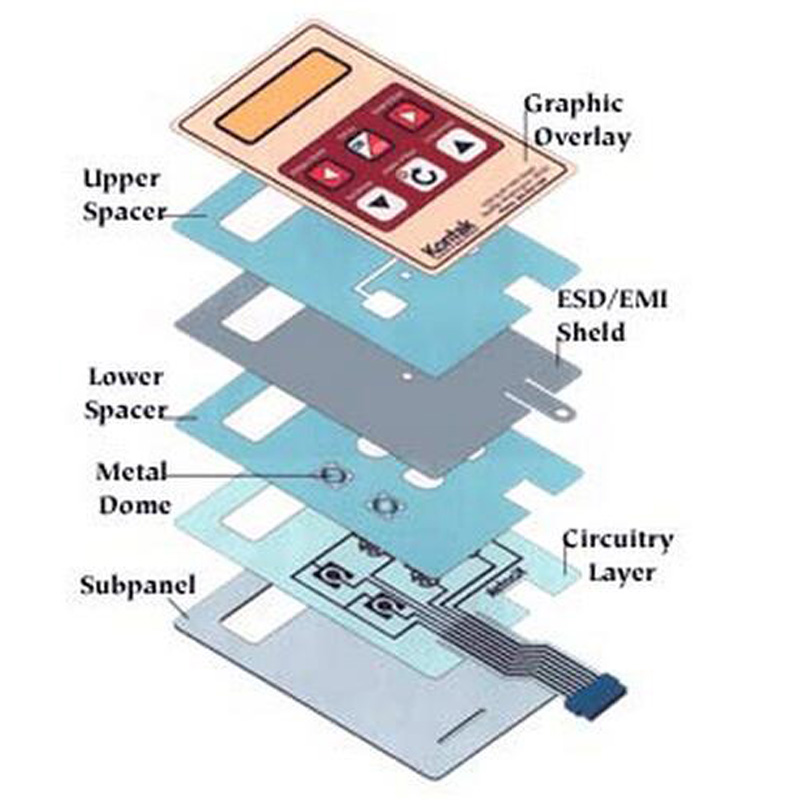

Tactile membrane switches come in many forms, the most commonly used are embossed tactile and metal dome tactile membrane keypads.

Tactile embossing generally includes upper circuit embossing and membrane panel embossing. Some very thin structures have removed the upper circuit, and the tactile points of the upper circuit are printed directly on the overlay panel. The embossing of the membrane switch is formed by hydraulically heating the mold, so that the button is raised and higher than the panel, forming a three-dimensional membrane switch button. The material is usually PET and PC, but PET has better toughness and heat shrinkability. PET material has better resilience, so light-touch membrane switches have a good sense of touch and more sensitive circuit performance, but PET materials should not be used in high temperature environments for a long time, high temperature will lead to weakened button tactility. Embossed membrane switches generally use the upper circuit and Panels with embossing. When there is no embossing on the upper circuit, the design of the ventilation groove of the interval layer should be considered, and the small hole of the upper circuit should be used as the ventilation hole, and the contact point of the lower circuit should be designed as an isolation point to avoid the hidden danger of circuit short circuit and circuit conduction; the contacts are directly printed on When it is on the panel, it is necessary to consider the deformation of the panel after high-temperature aging. If the high-temperature baking time is too long, the deformation of the panel will be large, which will bring great difficulties to the assembly and bonding of the membrane switch. If the high-temperature baking time is too short, the aging time of the panel contacts is not enough, the contacts are easy to wear, and the life of the product keypads is shortened.The general baking temperature is 120 degrees and 30-40 minutes.

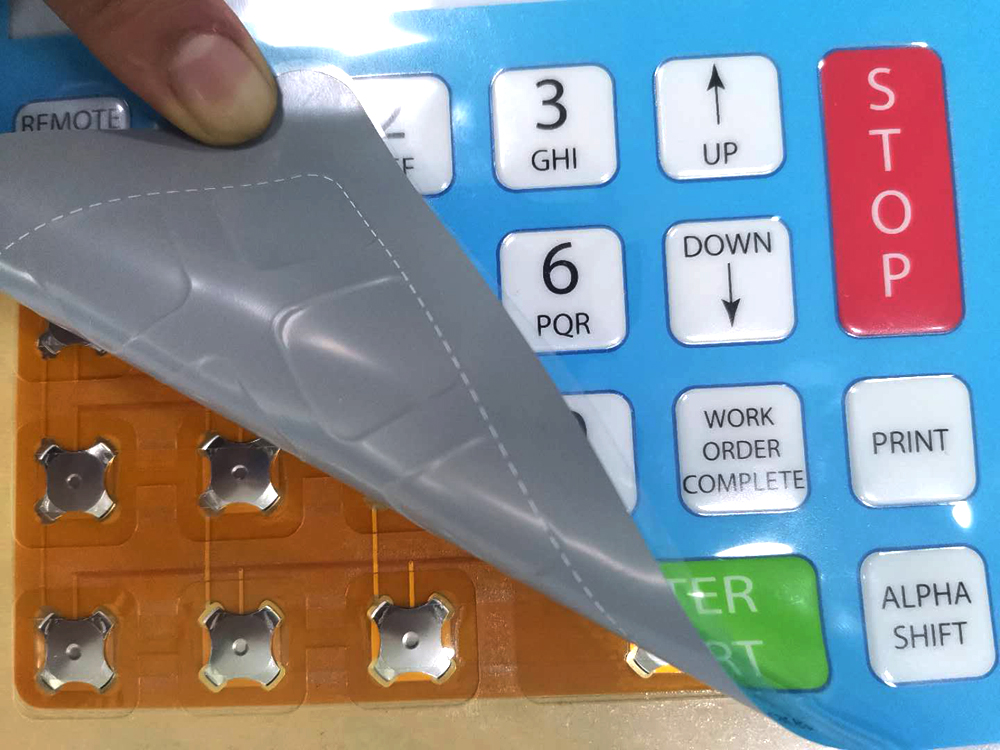

The metal dome tactile membrane keypad switch refers to fixing the metal dome on the lower circuit to form an upper circuit with a loop. When the metal dome is touched, the metal dome connects with the contacts of the lower circuit, forming a loop. The buttons of the metal dome light touch membrane switch keyboard can be designed in a variety of ways, which makes the product more stable and reliable, and at the same time enhances the decorative effect of the product to achieve a perfect appearance.

More information membrane switch visit:www.jcftechnology.com