Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

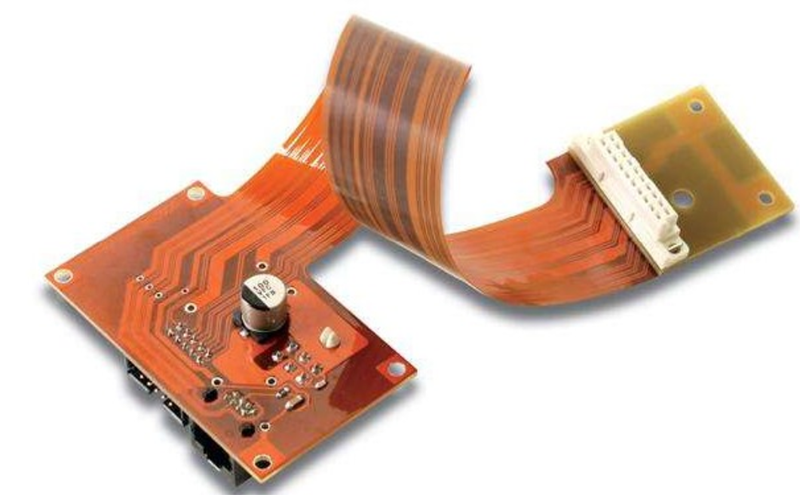

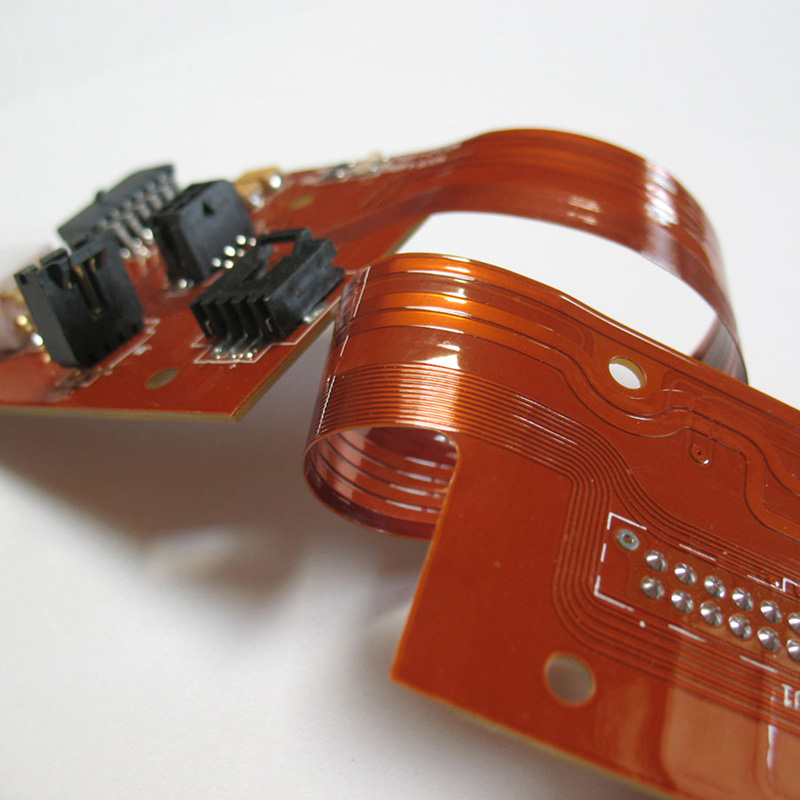

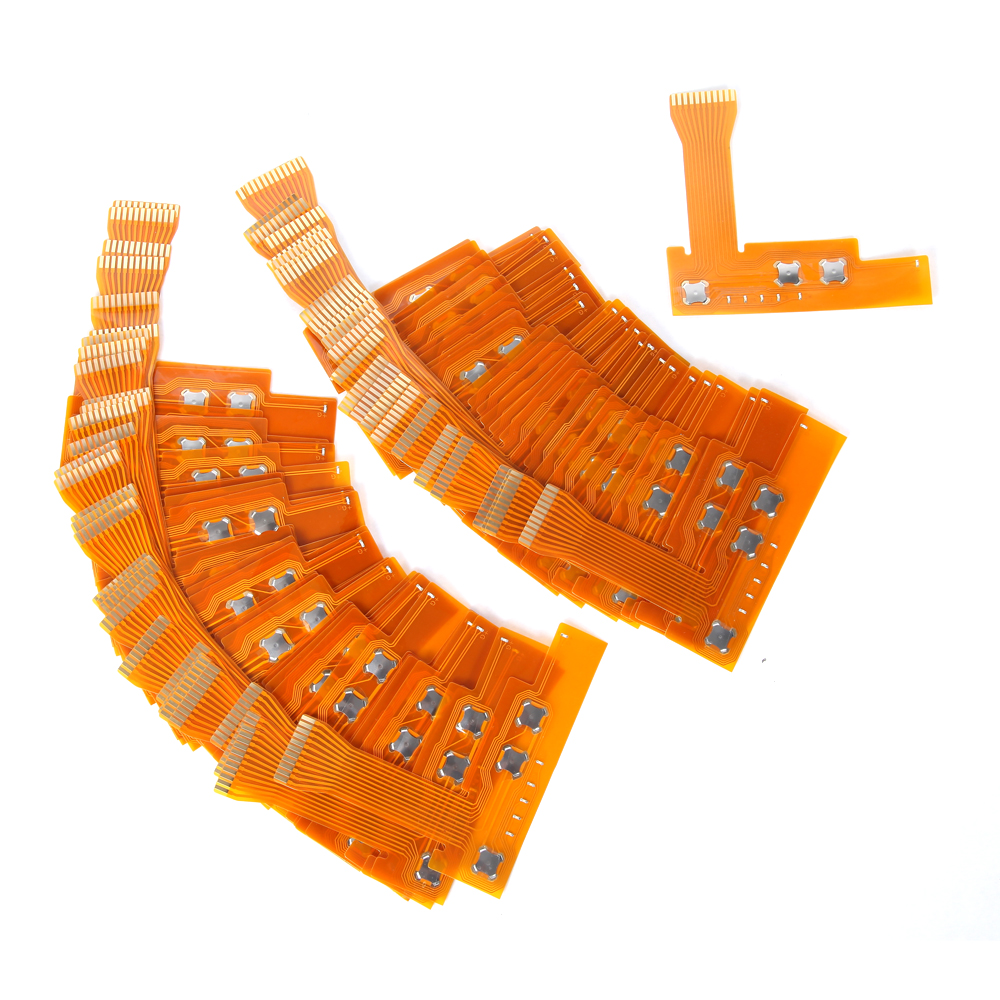

Flexible Printed Circuit (FPC) was previously a technology developed for the development of space rocket technology. It is made of polyester film or polyimide as the base material, which has high reliability and excellent flexibility. By embedding a circuit design on a flexible thin plastic sheet, a large number of precision components can be stacked in a narrow and limited space to form a flexible circuit. This kind of circuit can be bent and folded at will, light in weight, small in size, good in heat dissipation, easy to install, and breaks through the traditional interconnection technology. In the construction of flexible circuits, the materials are insulating films, conductors and adhesives. Flexible printed circuits are the solution to meet the miniaturization and mobility requirements of electronic products.

FPC flexible circuit boards are used in mobile phones, notebook computers, PDA, LCM, industrial equipment, electronic devices and other electronic products. FPC flexible circuit board is a kind of highly reliable and flexible printed circuit made of polyimide or polyester film as the base material. According to the combination method of substrate and copper foil, flexible circuit boards can be divided into two categories: flexible boards with glue and flexible boards without glue. Among them, the price of the non adhesive flexible board is more expensive than the adhesive flexible board, but its flexibility, the bonding force between the copper foil and the substrate, and the flatness of the pad are also better than the adhesive flexible board. Therefore, it is generally only used for those electronic products with high requirements; because not flexible boards with glue are very expensive, most of the flexible boards on the market now are flexible boards with glue. Because flexible boards are mainly used in occasions that require bending, if the design or process is unreasonable, defects such as micro-cracks and open welding will occur.

More information visit:www.jcftechnology.com

More information visit:www.jcftechnology.com