Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

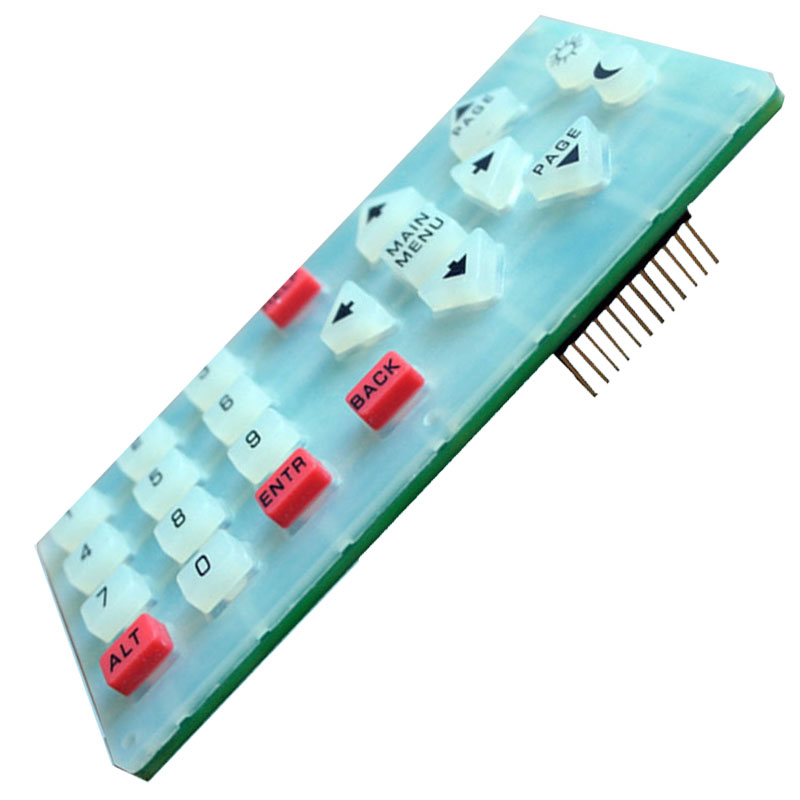

1,Design: The process starts with the design of the rubber silicone keyboard. This includes determining the layout of the keys, the overall shape and size of the keyboard, and any additional features such as custom symbols or backlighting.

2,Mold making: After the design is completed, the mold is made according to the specifications. Molds are usually made of durable materials such as metal or high-quality silicone. The mold is designed to withstand the high temperatures and pressures experienced during the molding process.

3,Silicone preparation: Prepare silicone rubber material for the molding process. This involves mixing silicone with various additives such as colorants, fillers, and curing agents. The specific formulation of the silicone material is critical to achieving the desired properties, such as flexibility, durability and tactile response.

4,Molding: Put the prepared silicone material into the mold, and close the mold under high pressure. The combination of pressure and heat causes the silicone to flow and conform to the shape of the mold, creating a rubber silicone keypad.

5,Curing: Then heat the mold containing the silicone material to solidify the silicone. Curing is a critical step for silicone to cure and develop its final properties. The duration and temperature of the curing process are carefully controlled to ensure the required hardness, elasticity and resistance to environmental factors.

6,Demold: After the silicone is completely solidified, open the mold and carefully take out the newly formed rubber silicone button. Check the quality of the keyboard and resolve any defects.

7,Post-processing: Depending on specific requirements, rubber silicone buttons may undergo additional post-processing steps. This may include trimming excess material, printing or laser-etching symbols and text, applying a protective coating, or assembling the keyboard with other components.

8,Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the rubber silicone keyboard meets the requirements for functionality, durability, and aesthetics. This may involve testing factors such as the keyboard’s actuation force, key travel, resistance to environmental conditions, and overall performance.

In summary, the production of rubber silicone keyboards involves a precise and controlled manufacturing process, from the initial design stages to final quality control inspections. Each step is critical to ensuring the keyboard meets necessary performance and reliability standards.

If you need further information silicone keyboard, please contact us,more information visit:www.jcftechnology.com