Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Membrane switches are versatile input devices used in various applications, from household appliances to industrial equipment. They generally consist of multiple layers of flexible material with conductive traces and are designed to provide a user interface in a compact form factor. Here are the primary types of membrane switches:

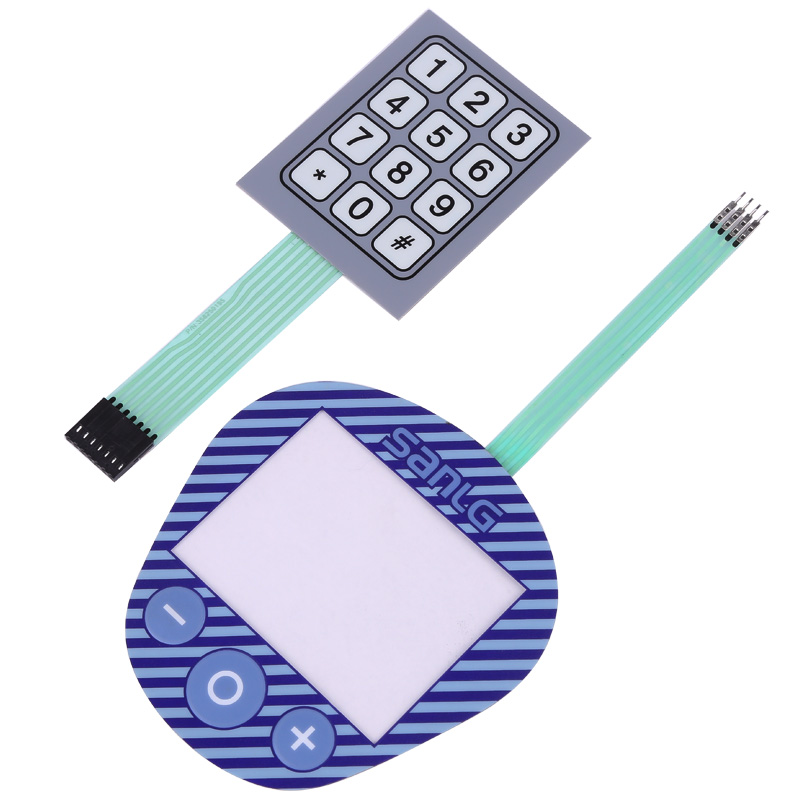

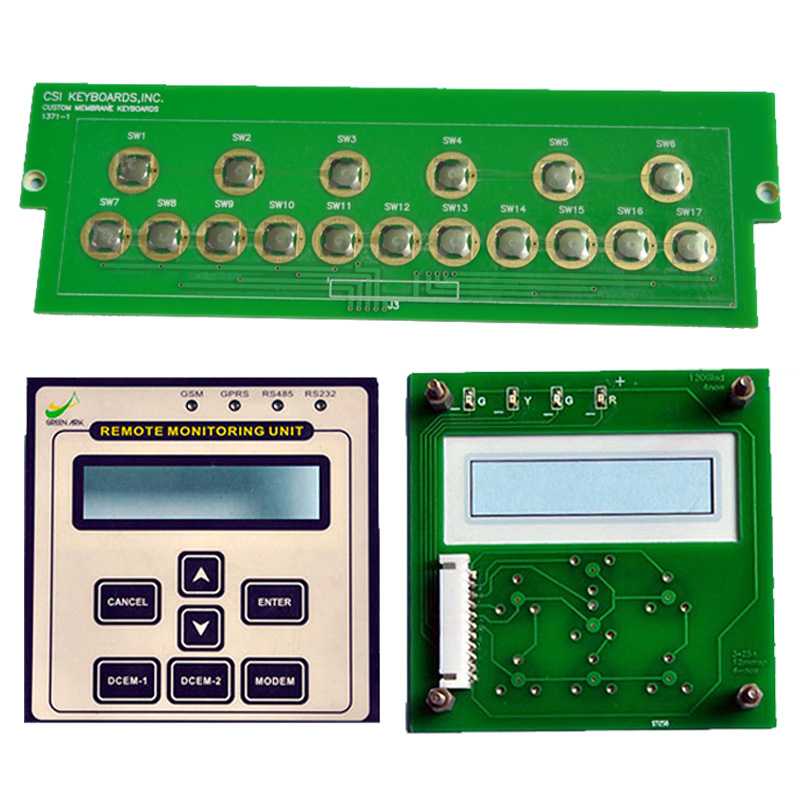

1. Conductive Membrane panel SwitchesStandard Membrane Switches: Basic membrane switches that use conductive ink or conductive traces printed on a flexible film to register button presses.

Capacitive Membrane Switches: Utilize capacitive sensing technology to detect touch without physical contact. They are more durable and offer a modern, sleek design.

Combination of Membrane and Mechanical Switches: Integrate membrane switch technology with mechanical switches or tactile elements. This hybrid approach provides both the durability of mechanical switches and the design flexibility of membrane switches.

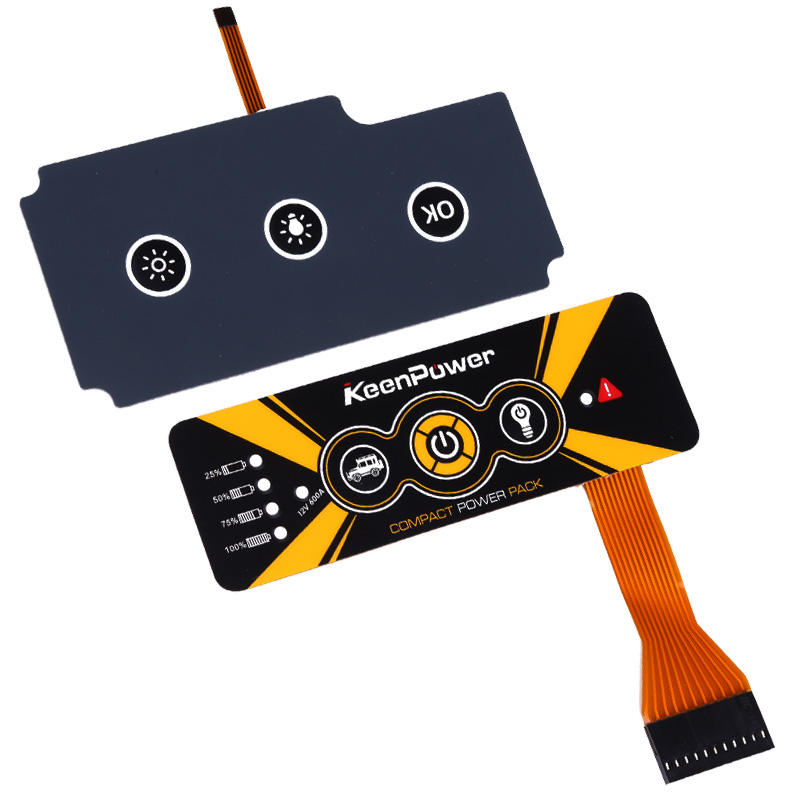

Backlit Membrane Switches: Feature integrated LED backlighting to illuminate the switch labels or symbols, improving visibility in low-light conditions.

Edge-Lit Membrane Switches: Use LED lights placed around the edges of the switch to create an illuminated effect.

Tactile Feedback Membrane Switches: Include a tactile dome or a similar feature to provide physical feedback when the switch is pressed, enhancing user experience.

Industrial Membrane Switches: Designed to withstand harsh environments, these switches are often used in industrial applications and are built to resist extreme temperatures, moisture, and physical wear.

Custom-Designed Membrane Switches: Tailored to specific requirements, including unique shapes, sizes, colors, and graphic designs. These switches are often used when off-the-shelf solutions do not meet the design or functional needs.

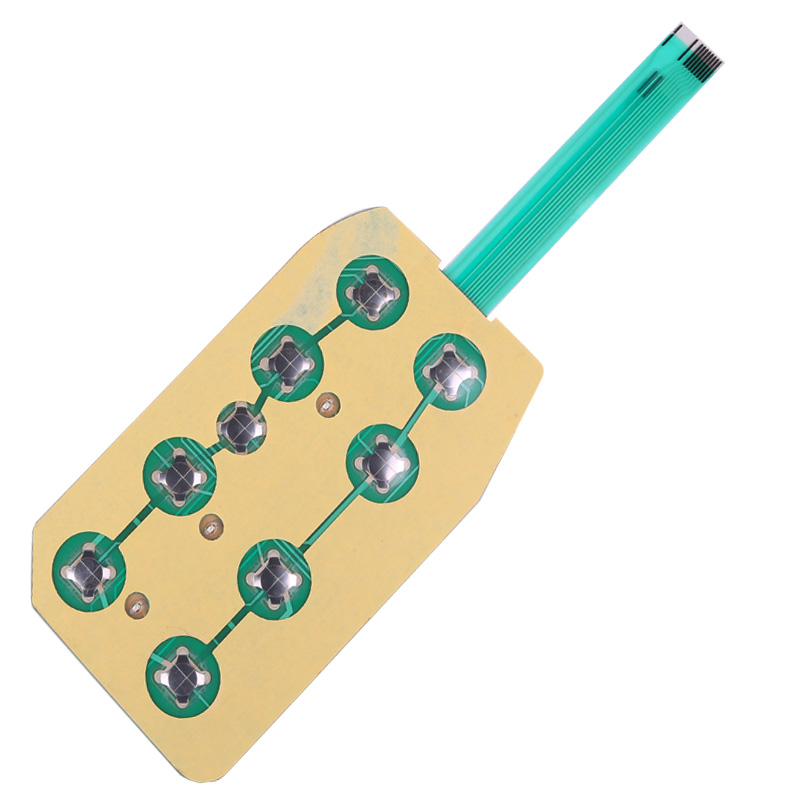

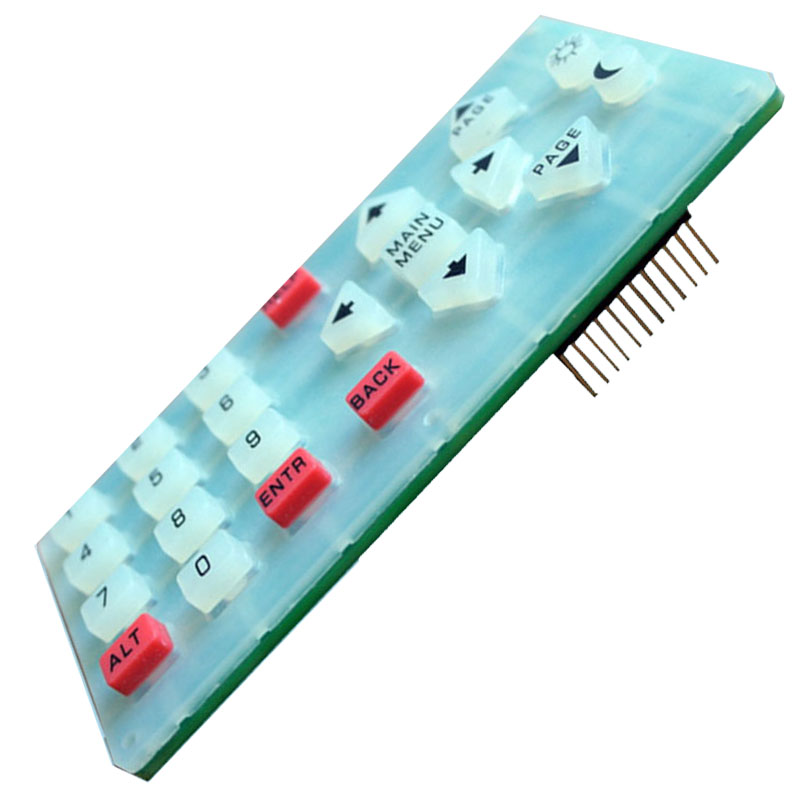

Flexible Printed Circuit (FPC) Membrane Switches: Utilize a flexible printed circuit board to create a switch that can conform to various shapes and surfaces, offering greater design flexibility.

PCB (or printed circuit board), is typically made of copper-clad cloth or fiber infused into a resin material. The cloth/fiber used, along with the resin material, creates a cloth-to-resin ratio to determine the laminate’s type designation (FR-4, CEM-1, G-10, etc.). FR-4 is the most common material used today.

Silicone rubber keypads are the most widely used form of switch technology today. We offer reliability, long life and design flexibility.

Each type of membrane switch is designed to address specific needs in terms of durability, aesthetics, and functionality. The choice of switch depends on the application, environmental conditions, and user requirements.

If you need further information membrane switch,more information visit:www.jcftechnology.com