Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

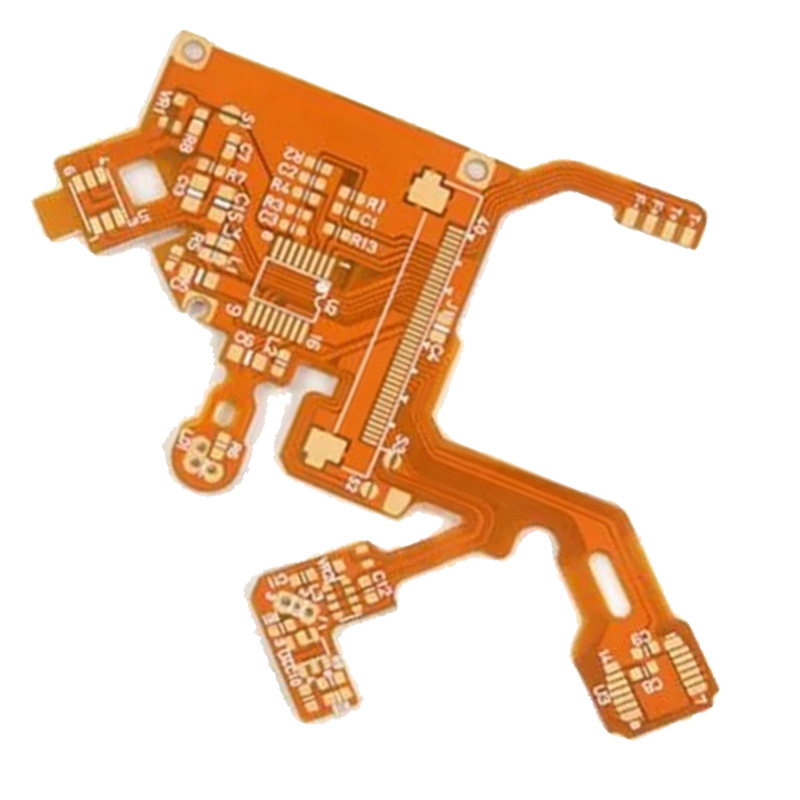

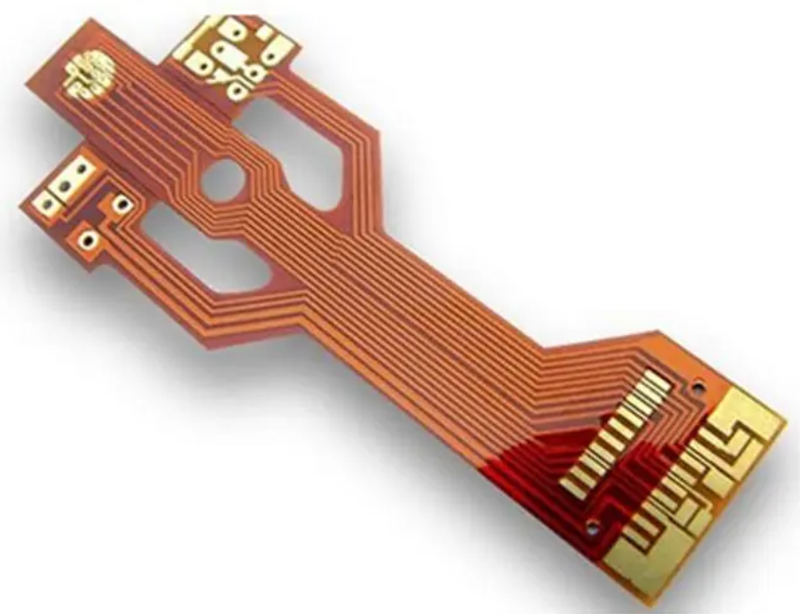

A Flexible Printed Circuit (FPC) is a type of circuit board that is made from flexible materials, allowing it to bend, twist, and conform to different shapes and spaces. This flexibility contrasts with traditional rigid printed circuit boards (PCBs), which are stiff and fixed in shape.

Key Features of FPCs:

Flexibility: FPCs are built on a flexible substrate, usually a polymer film like polyimide, which allows them to be bent or folded. This flexibility enables them to fit into compact or irregularly shaped spaces.

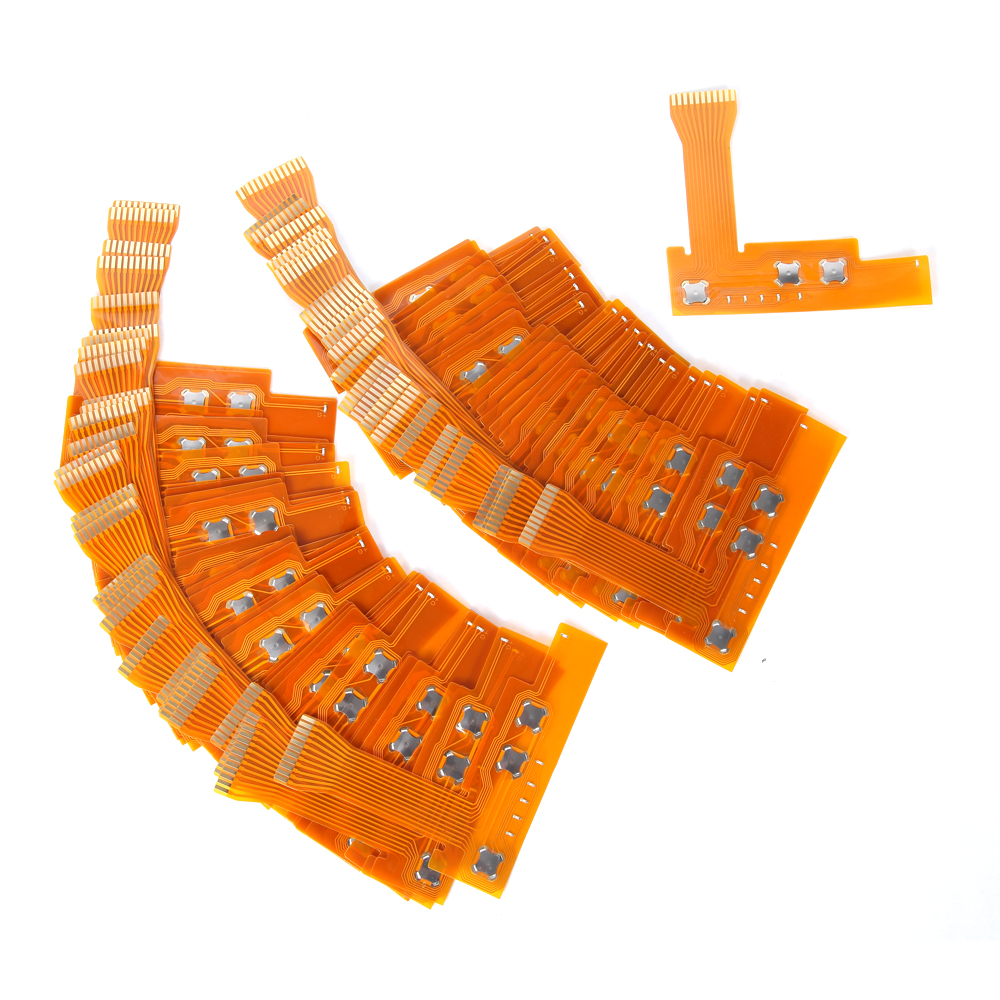

Lightweight and Space-Efficient: Because they are thinner and lighter than rigid PCBs, FPCs help in reducing the overall weight and size of electronic devices. This is particularly useful in applications where space is limited.

Durability: Flexible circuits can handle mechanical stress, vibrations, and movements better than rigid boards. They are designed to withstand dynamic conditions without compromising performance.

Electrical Performance: FPCs can offer good electrical performance with low inductance and resistance. They can be designed with multiple layers to achieve the desired electrical characteristics.

Integration and Connectivity: They are often used to connect various components in a device, providing a pathway for electrical signals and power. This is especially useful in consumer electronics like smartphones, tablets, and wearables.

Applications:

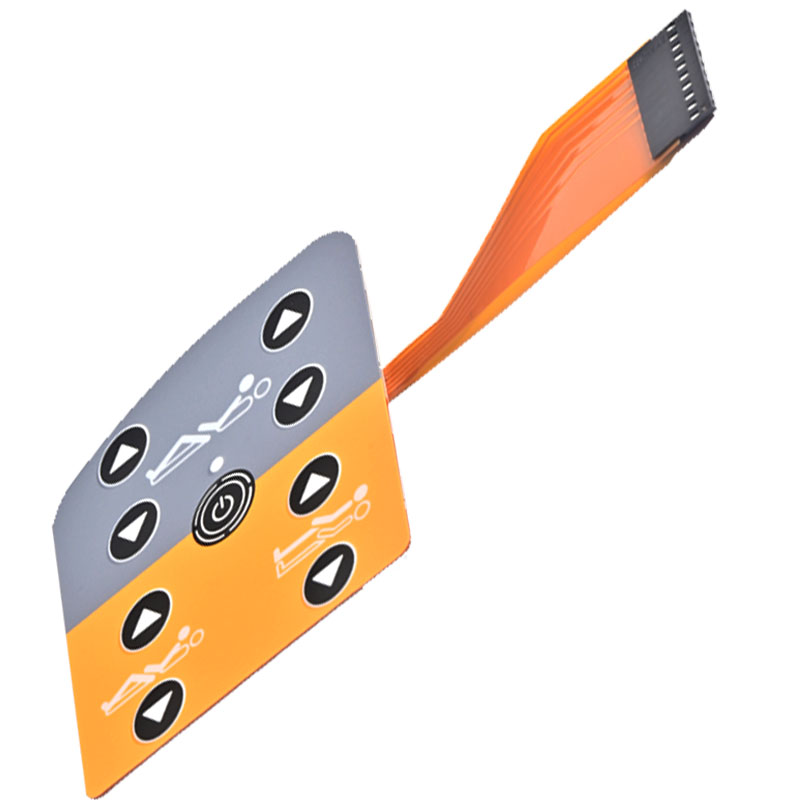

Consumer Electronics: Used in smartphones, tablets, and other compact devices where space is a premium.

Wearable Devices: Ideal for devices like smartwatches and fitness trackers, where the circuit needs to conform to the shape of the wearable.

Automotive: Employed in applications where flexibility is needed to fit around complex shapes and components.

Medical Devices: Used in medical equipment and implants where flexible circuits can adapt to body contours and movement.

Construction:

An FPC typically consists of several layers:

Substrate: The base material that provides flexibility (e.g., polyimide film).

Conductive Traces: Layers of metal (usually copper) that form the electrical pathways.

Coverlay: An insulating layer that protects the conductive traces and provides additional flexibility and durability.

FPCs offer significant advantages in terms of design flexibility and space savings, making them essential in modern electronics where compact and adaptable designs are crucial.

More information visit:www.jcftechnology.com