Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

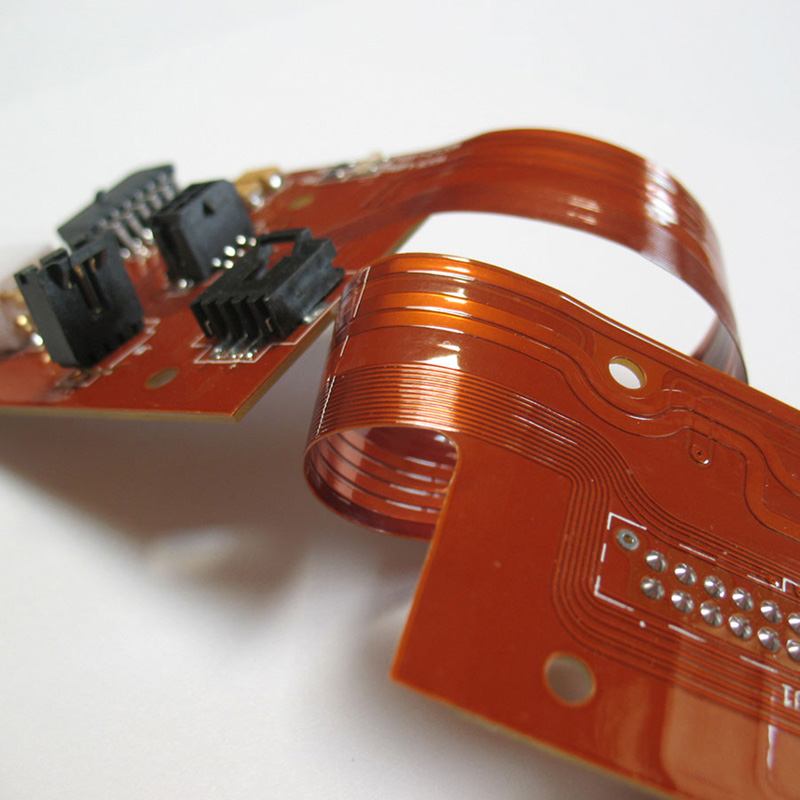

The difference between a flex circuit and a PCB

Flex circuits and printed circuit boards (PCBs) are both used for connecting electronic components, but they differ in design, materials, and applications. Here’s a breakdown of the key differences:

1. Material and Structure:

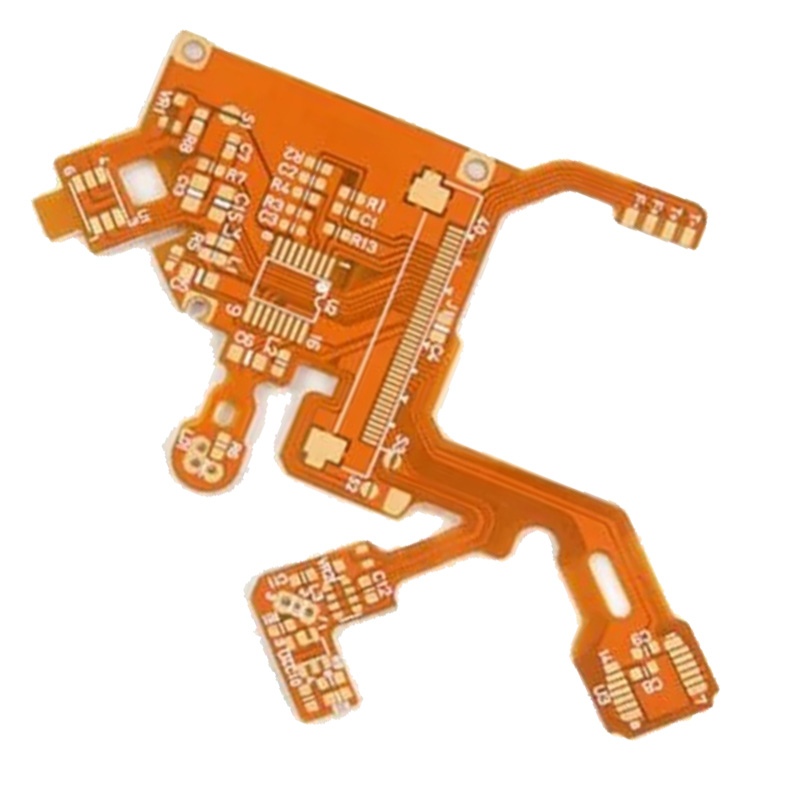

Flex Circuit:

Made of flexible materials, typically polyimide or polyester films, that allow the circuit to bend and twist.

Consists of a thin, flexible substrate with copper conductors.

The flexibility allows it to fit into compact spaces or to move with other parts of a device.

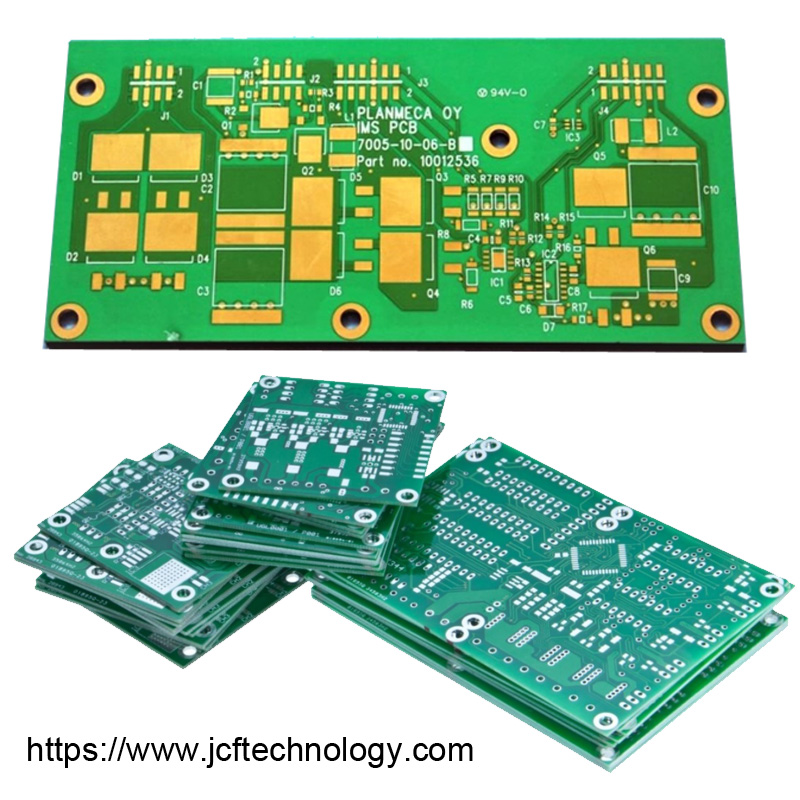

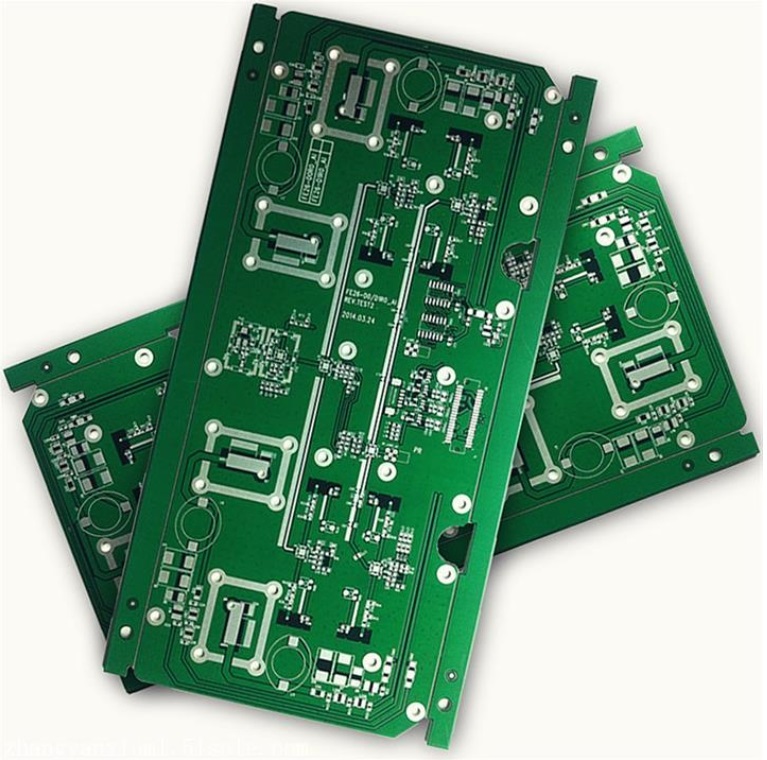

PCB (Printed Circuit Board):

Made of rigid materials, typically FR4 (a fiberglass-reinforced epoxy laminate).

Consists of multiple layers of copper traces on a solid substrate.

The rigid structure provides a stable base for components and is used in most standard electronic devices.

2. Design and Application:

Flex Circuit:

Used in applications where the circuit needs to bend, fold, or flex, such as in smartphones, wearable devices, cameras, and medical devices.

Often used to connect different parts of a device that move relative to each other, like the hinge in a laptop.

PCB:

Used in most electronic devices where flexibility is not needed, such as in computers, TVs, and other home electronics.

Designed to provide a stable, unmoving base for electronic components.

3. Durability:

Flex Circuit:

Designed to withstand mechanical stress from bending and flexing.

More resistant to vibrations and movement due to their flexibility.

PCB:

Rigid and more susceptible to damage if subjected to mechanical stress like bending or twisting.

Generally more durable in environments where no movement is expected.

4. Cost:

Flex Circuit:

More expensive to manufacture due to the complex design and materials used.

The cost is often justified in applications where flexibility is crucial.

PCB:

Less expensive and easier to produce in large volumes.

Commonly used in mass-produced electronic devices.

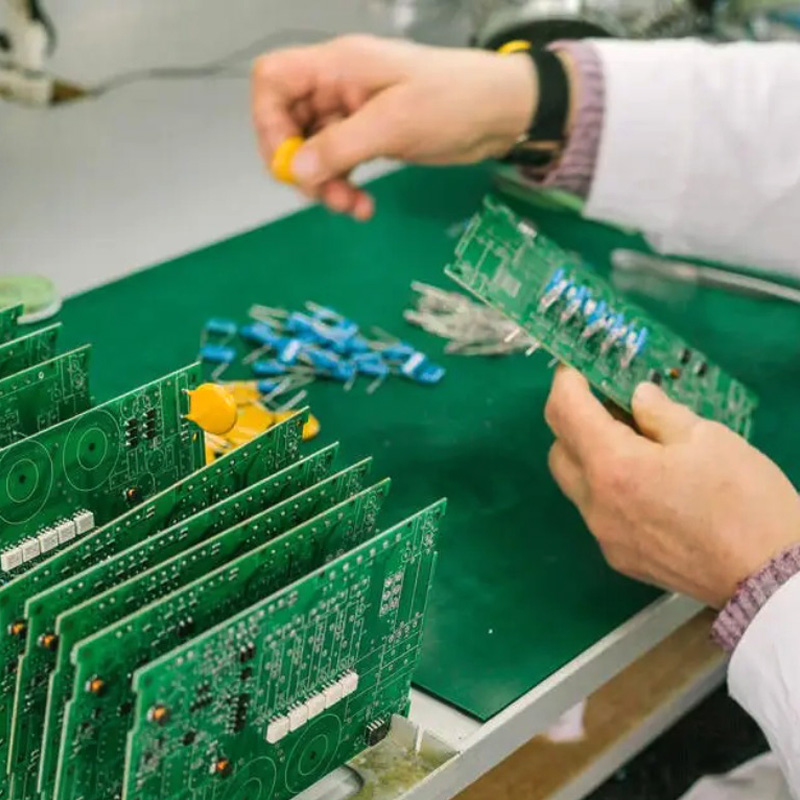

5. Assembly:

Flex Circuit:

Can be more complex to assemble due to its flexibility.

Requires specialized manufacturing techniques to handle the flexible substrate.

PCB:

Easier to assemble due to its rigidity.

Standardized manufacturing processes are widely available.

6. Layers:

Flex Circuit:

Typically has fewer layers compared to PCBs, although multilayer flex circuits do exist.

The layers are designed to flex and move without breaking.

PCB:

Can have many layers (multi-layer PCBs) to accommodate complex circuit designs.

The layers are rigid and do not move.

7. Thermal Management:

Flex Circuit:

Polyimide, the common material used, has good thermal stability, which is beneficial in high-temperature environments.

PCB:

Rigid PCBs often use materials like FR4, which also have good thermal properties but may not perform as well as flex circuits in extreme conditions.

In summary, flex circuits are used where flexibility and space-saving are critical, while rigid PCBs are used for most standard electronic applications where a stable and unmoving platform is required.

More information visit:www.jcftechnology.com