Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Choosing the right raw materials for membrane switches is crucial for ensuring their performance, durability, and compatibility with the intended application. The materials must be selected based on factors such as environmental conditions, mechanical requirements, cost, and the desired user experience. Below is a guide to help in selecting the raw materials for membrane switches:

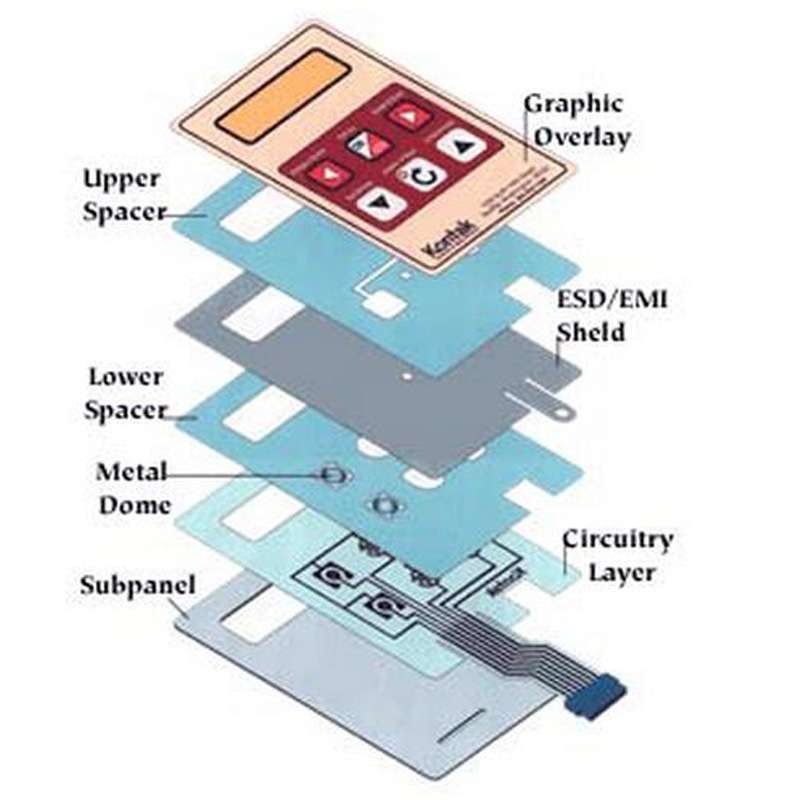

1. Membrane switch top Layer (Graphic Overlay)

The graphic overlay is the visible part of the membrane switch and needs to withstand wear, resist chemicals, and provide good visual clarity. When selecting materials for the top layer, consider the following:

Material Options:

Polyester (PET): Durable, cost-effective, and resistant to chemicals, UV light, and abrasion. It is commonly used for graphic overlays in standard applications.

Polycarbonate (PC): Offers excellent clarity and is more rigid than polyester. It is more resistant to impact and is often used in environments where the switch will face more mechanical stress or abrasion.

Acrylic (PMMA): Offers high clarity and UV resistance but is more brittle compared to polycarbonate and polyester.

2. Membrane panel spacer Layer

The spacer layer separates the conductive layers and ensures that the circuit is not closed unless the switch is pressed. This layer is critical for providing the necessary insulation.

Material Options:

Polyester (PET): Commonly used as a spacer due to its flexibility and insulating properties.

PVC: Less expensive than polyester and still provides good insulation and flexibility.

Polyimide (PI): High-temperature resistance and good electrical insulating properties, used for more demanding applications.

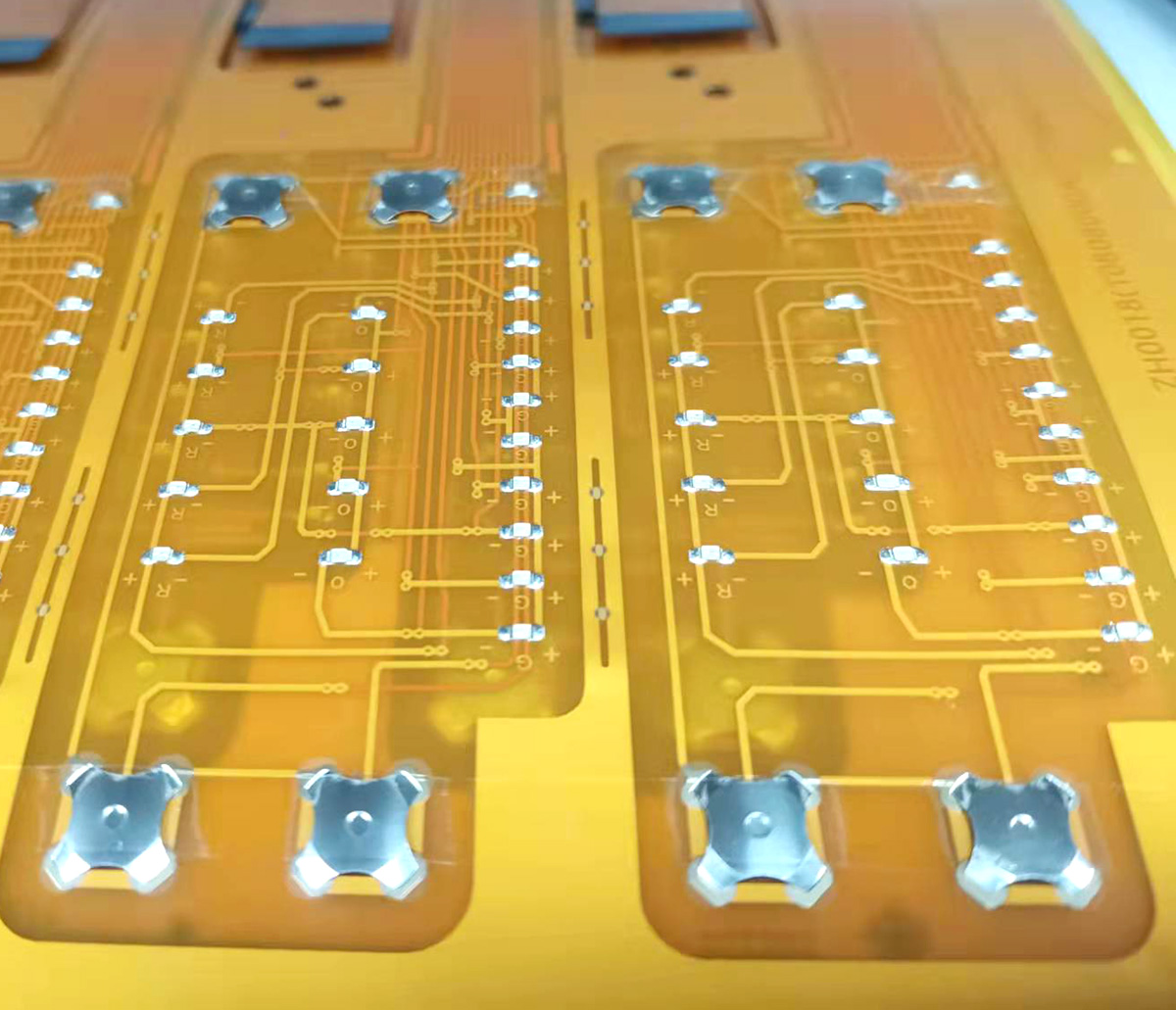

3. Membrane keypad conductive Layers

The conductive layers form the electrical circuit that allows the switch to send a signal when activated. These layers need to have a high level of conductivity, durability, and flexibility.

Material Options:

Silver Ink: The most common material for conductive traces, as it offers excellent conductivity and is widely available. However, silver is more expensive than alternatives.

Carbon Ink: Less conductive than silver ink, but cheaper and suitable for less demanding applications. It is also more resistant to corrosion.

Copper: Used in some designs but requires a more complex manufacturing process and might not be as flexible as silver ink or carbon ink.

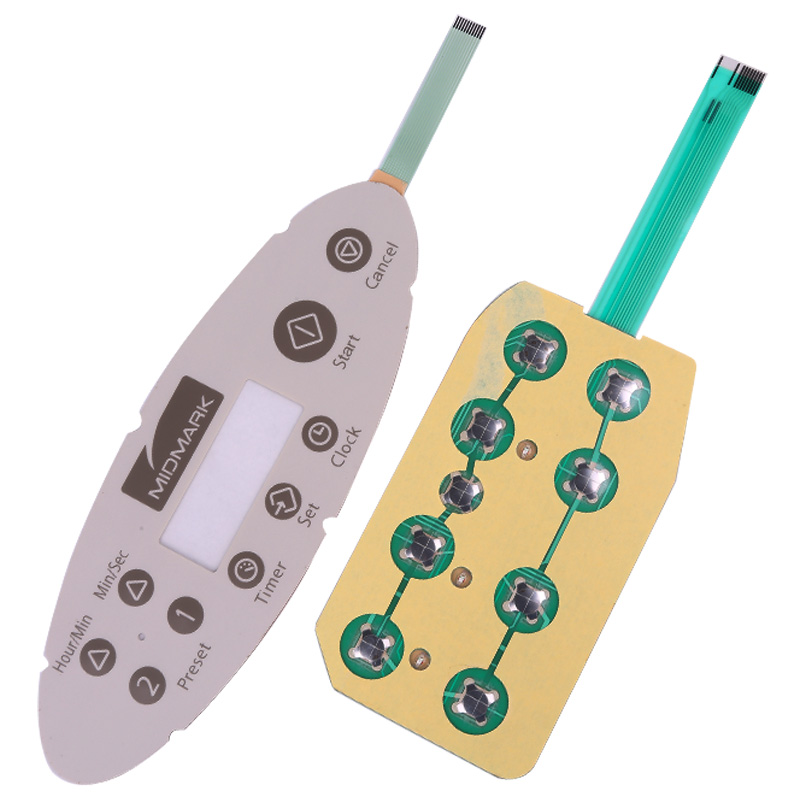

4. Membrane keyboard domes (Tactile Feedback)

Tactile domes are often included in membrane switches to provide physical feedback to the user, making it clear when a key has been activated. These can be made of metal or plastic.

Material Options:

Stainless Steel: Provides good spring action and durability. It’s widely used for tactile feedback because it’s resilient and maintains its shape over time.

Copper Alloy: More cost-effective than stainless steel, but it may have a shorter lifespan.

Polymer/Plastic Domes: Some designs use molded plastic domes for tactile feedback, which are typically lighter and less expensive than metal domes.

5. Membrane button adhesive Layer

The adhesive is used to bond the layers of the membrane switch together, ensuring they stay intact during use and preventing environmental contaminants from entering.

Material Options:

Acrylic Adhesive: Strong and durable, it provides good adhesion and flexibility.

Rubber-based Adhesive: Provides strong adhesion but may degrade over time if exposed to heat or chemicals.

Pressure-Sensitive Adhesive (PSA): Common for quick application and easy removal, offering flexibility and ease of use.

To choose the right raw materials for a membrane switch, the designer needs to balance factors such as environmental conditions (temperature, moisture, chemicals), mechanical properties (durability, flexibility), user experience (tactile feedback, clarity of graphics), and cost. By carefully selecting materials for each layer of the switch, you can ensure the final product meets the required performance and longevity for the specific application.

More information visit:www.jcftechnology.com