Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

To prevent short circuits in the membrane switch circuit layer, follow these best practices:

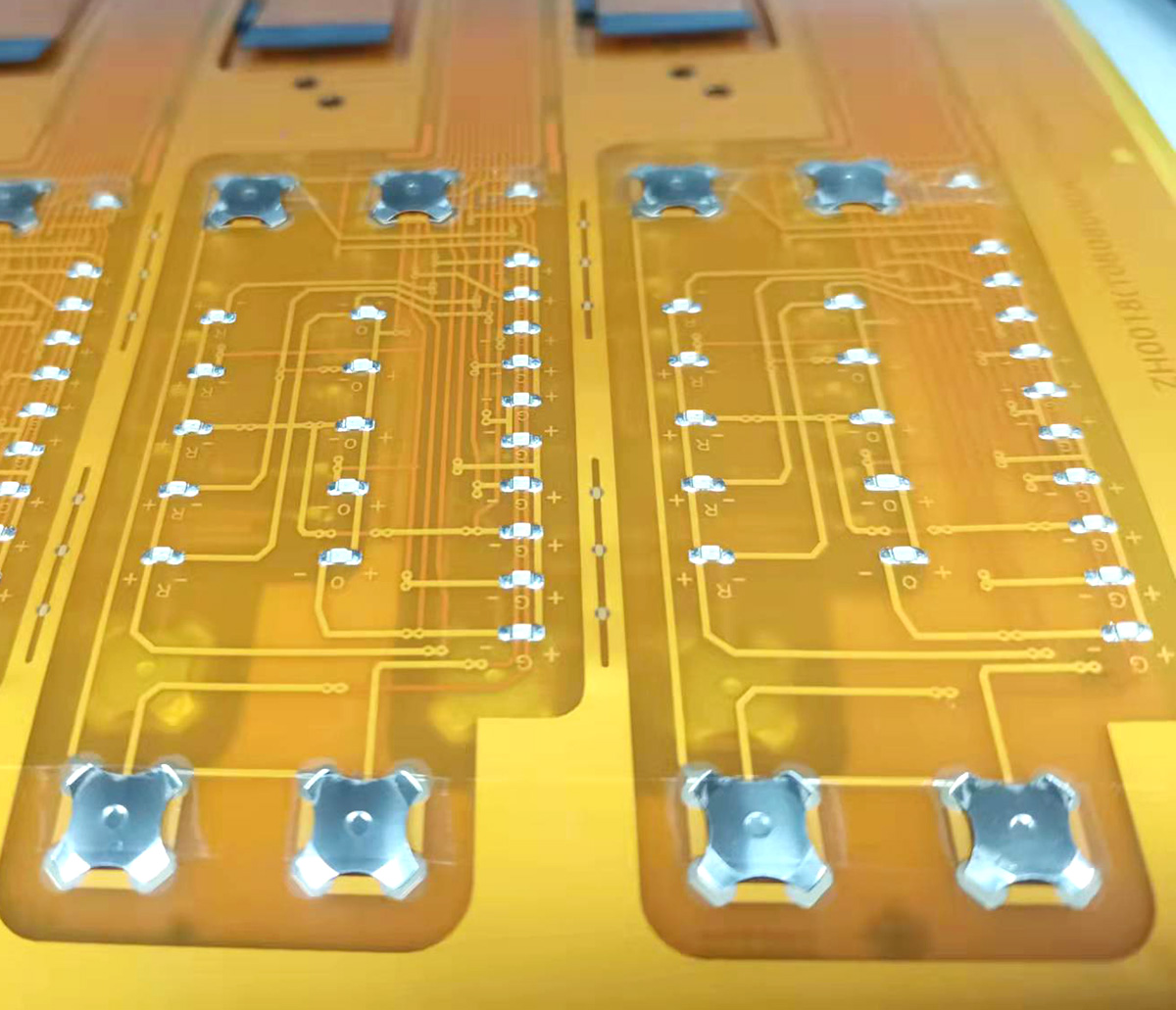

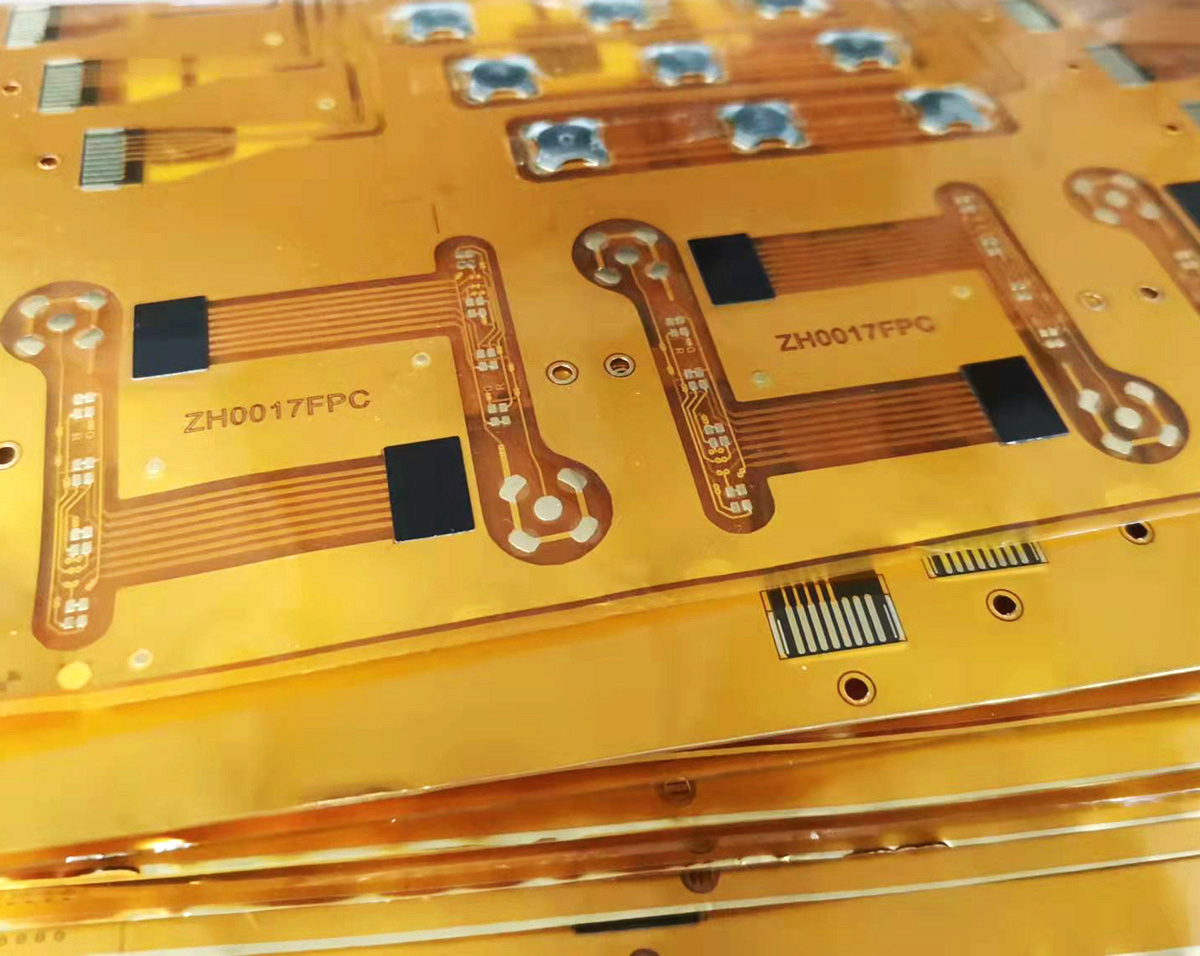

1. Membrane Circuit Layer Use Insulating Materials

Use insulating substrates: Membrane switches typically have a flexible substrate made from materials like polyester or polyimide, which insulate the conductive traces from each other. Ensure these materials are of high quality and meet your design's electrical insulation requirements.

Proper adhesive selection: Use non-conductive adhesives to prevent unintentional short circuits, especially where conductive traces may come into contact with each other.

2. Clear Trace Design

Adequate trace separation: Make sure that there is enough space between conductive traces to avoid accidental shorts. This is particularly important in high-density designs.

Use robust trace width guidelines: Proper trace width ensures adequate current carrying capacity without causing unnecessary heating, which could lead to melting and shorts.

Use routing software: Use advanced PCB design software with DFM (Design for Manufacturing) checks that alert you to potential short circuit areas before manufacturing.

3. Avoid Overlapping Conductors

Do not overlap traces: Ensure that conductive paths on different layers don’t overlap or come into contact when the switch is pressed, which could cause shorts. This can be checked during the design phase.

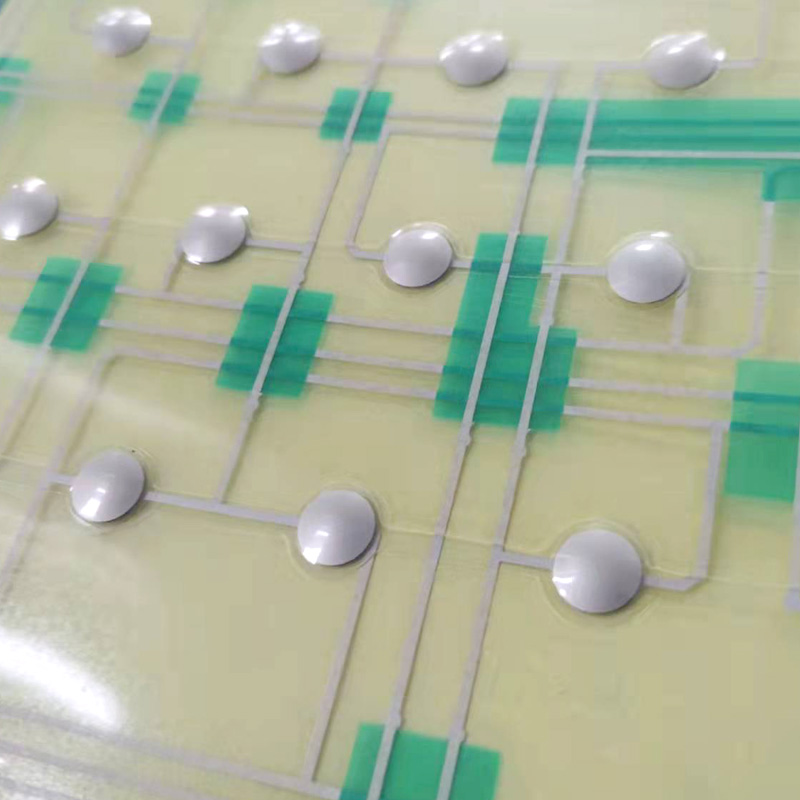

4. Use Protective Coatings

Apply protective coatings (like conformal coatings): Conformal coatings can be applied to prevent moisture, dust, and contaminants from bridging conductive traces and causing shorts.

Screen printing for protection: Screen printing dielectric materials over the conductive areas can add an additional layer of protection, preventing accidental shorts.

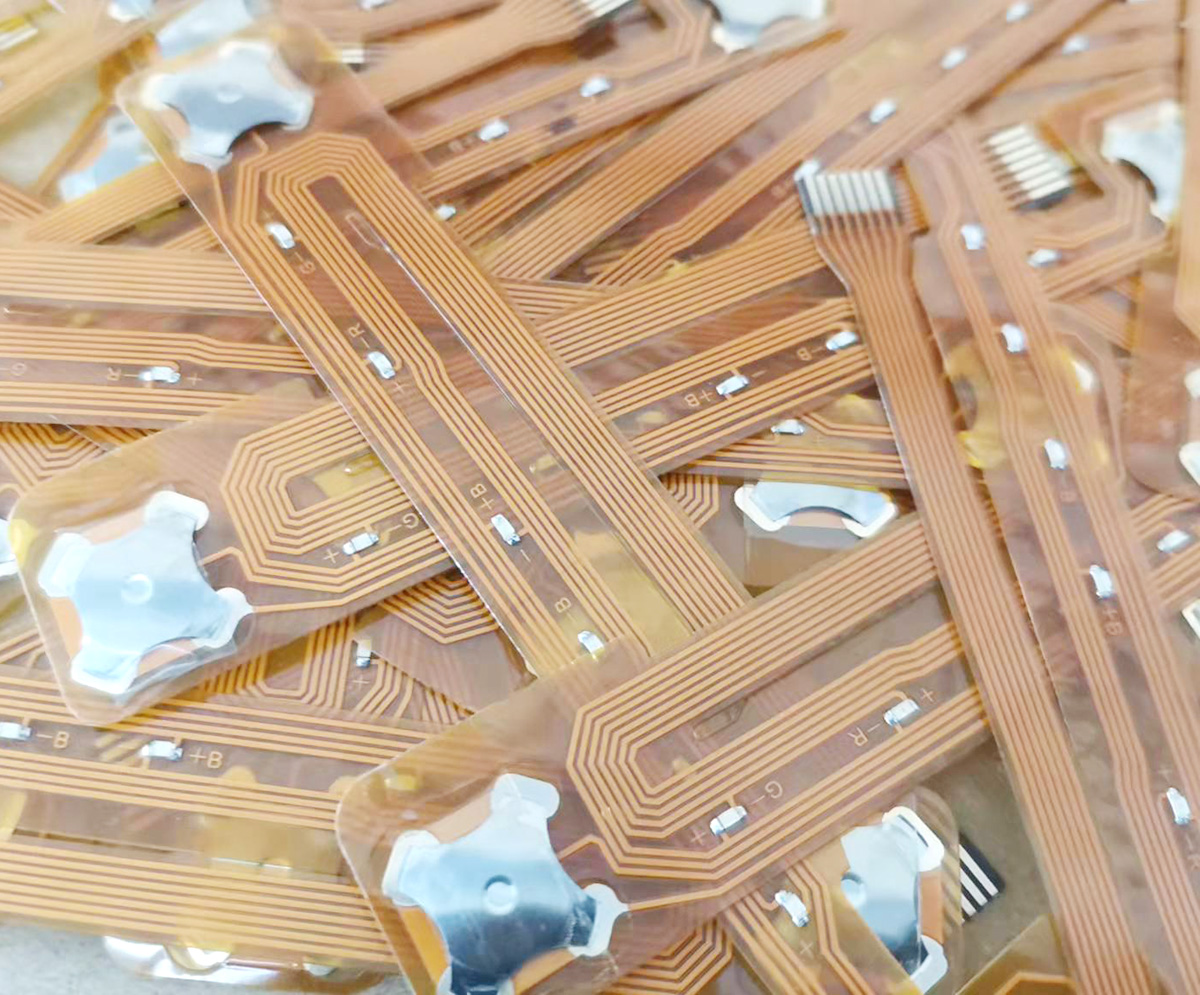

5. Membrane Keypad Layer Management

Correct layer alignment: Membrane switches are made up of several layers, such as the top overlay, the conductive layer, and the bottom layer. It is critical to ensure proper alignment during assembly to avoid any accidental contact between conductive areas on different layers.

6. Proper Pressure Control

Even pressure distribution: Membrane button often rely on pressure-sensitive contact to complete the circuit. Ensure that the switch is designed so that pressing doesn’t cause any unexpected electrical connections between layers.

7. Thorough Testing

In-circuit testing: Implement electrical testing methods, such as continuity checks, before finalizing assembly. This ensures that no short circuits are present in the switch circuit.

Functional testing: Perform functional tests that simulate normal operation, ensuring that no electrical paths are unintentionally closed during use.

8. Select Components Carefully

Choose components with proper ratings: Ensure all components, including resistors, capacitors, and diodes, are rated for the operating conditions of the membrane switch circuit.

Check for compatibility: Ensure all materials, such as conductive inks or traces, are compatible and do not cause shorting due to material properties.

By following these guidelines, you can significantly reduce the chances of a short circuit in your membrane switch design and ensure a reliable and functional product.

More information visit:www.jcftechnology.com