Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Yes, membrane keypads can be customized to meet specific design and functional requirements.

Membrane Switch Kedypad Process for Customization:

1,Design Phase: Work with a manufacturer to create CAD drawings or prototypes based on your specifications (e.g., key layout, dimensions, and functionality).

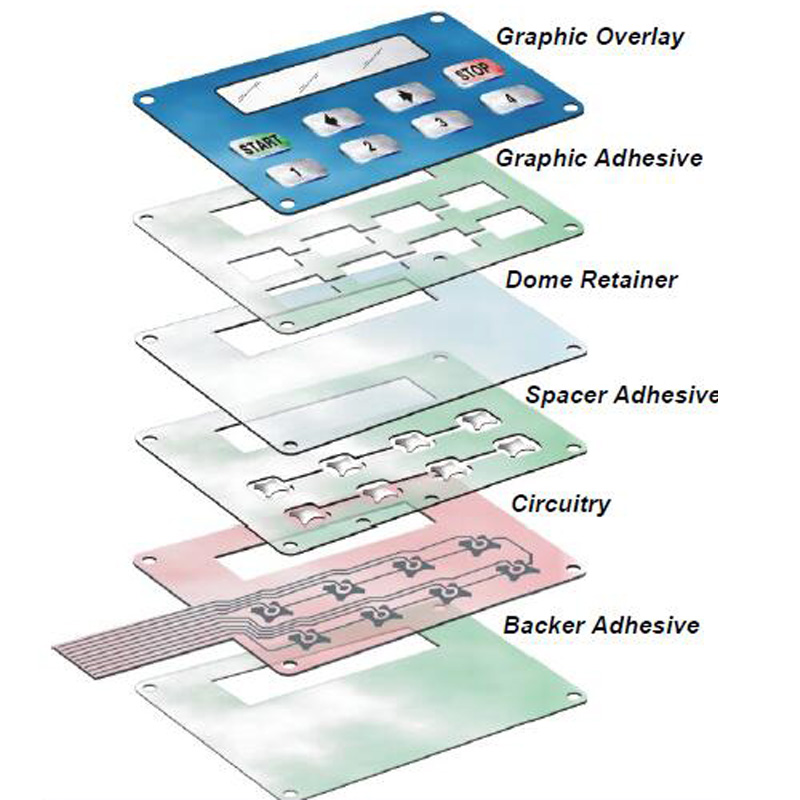

2,Material Selection: Choose materials based on environmental needs, durability, and aesthetics(e.g., PET,PC,3M adhesive).

3,Prototyping: Test a prototype to ensure functionality, tactile feel, and durability.

4,Production: Manufacturers use processes like screen printing, laser cutting, Tools and lamination to produce the final keypad.

Customize Membrane Keypad Additional Features:

Embossing: Raised keys or borders for tactile guidance.

Capacitive Touch: Integrate capacitive sensing for touch-sensitive controls.

Haptic Feedback: Add matel dome for enhanced user interaction.

Custom Shapes/Sizes: Die-cut keypads to fit unique enclosures or space constraints.

Customize Membrane Keyboard Considerations:

MOQ (Minimum Order Quantity): Custom keypads often require a minimum order, though some manufacturers offer low MOQs

for prototypes or small runs.

Cost: Customization costs depend on complexity, materials, and order volume. Simple designs are more cost-effective.

Lead Time: Custom designs typically take 2-8 weeks, depending on complexity and manufacturer capabilities.

Testing: Ensure the keypad meets standards like specific industry requirements .

More info visit:www.jcftechnology.com