Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

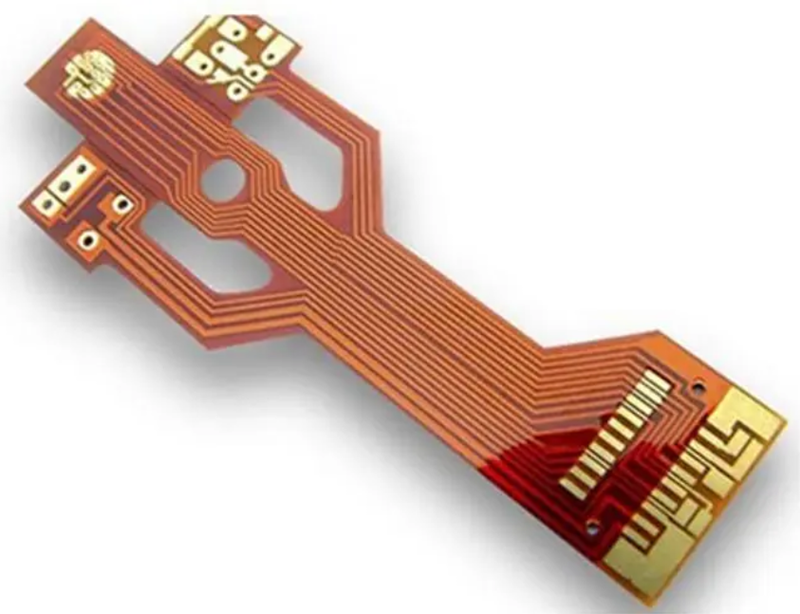

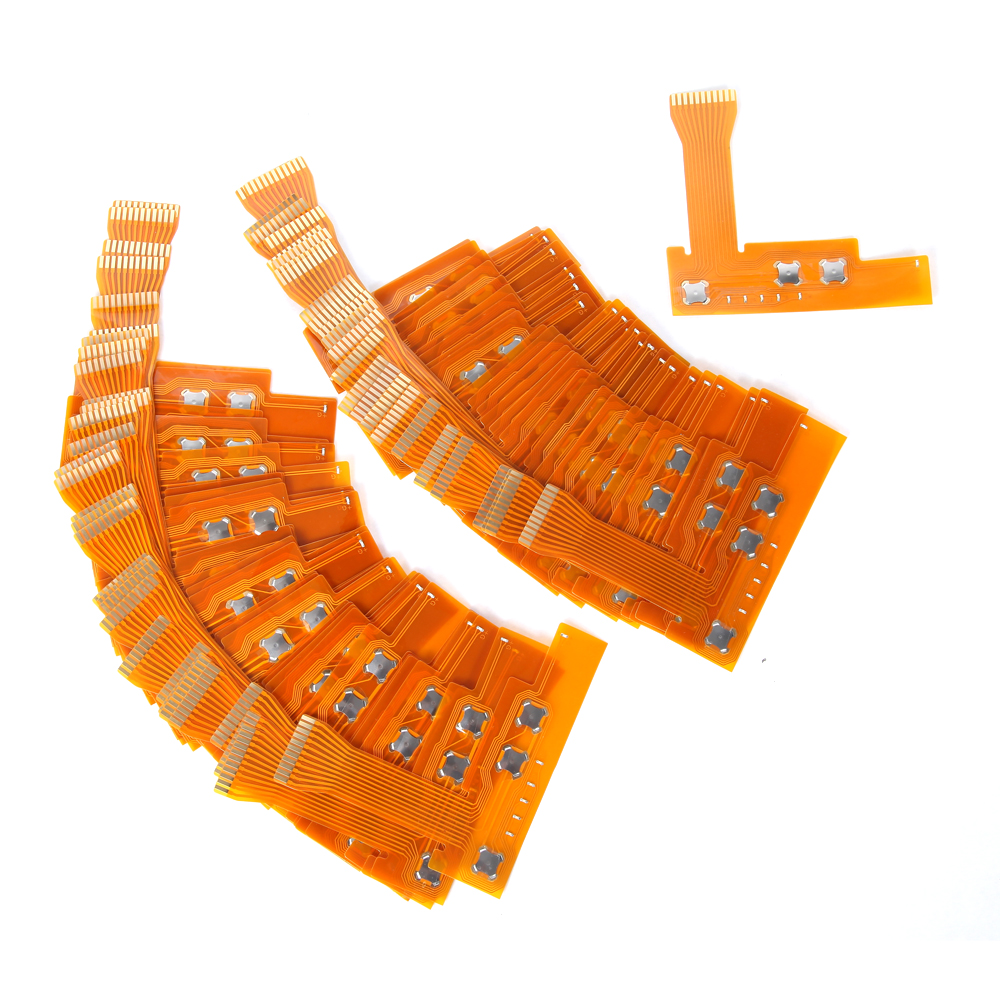

Flexible printed circuits made

Flexible printed circuits (FPCs) are made through a series of manufacturing steps that combine materials science, photolithography, and precise fabrication techniques. Here’s a concise overview of the process:

1. Substrate Selection: The process starts with a flexible substrate, typically polyimide (e.g., Kapton) or polyester, chosen for its flexibility, heat resistance, and electrical insulation properties.

2. Copper Lamination: A thin layer of copper foil is laminated onto the substrate using adhesive or adhesive-less methods to form a copper-clad laminate. This copper will form the conductive traces.

3. Photoresist Application: A light-sensitive photoresist layer is applied to the copper surface.

4.Flexible Circuit Patterning (Photolithography):

- A photomask with the desired circuit pattern is placed over the photoresist.

- The assembly is exposed to UV light, hardening (or softening, depending on the resist type) the exposed areas.

- Unexposed photoresist is washed away, revealing the copper to be etched.

5. Etching: The exposed copper is chemically etched away, leaving the desired circuit pattern protected by the photoresist. The remaining photoresist is then removed.

6. Drilling and Cutting: Holes for vias or component mounting are drilled using laser or mechanical methods. The FPC may also be cut to its final shape.

7. Coverlay Application: A protective coverlay (a flexible insulating film) or solder mask is applied over the circuit to protect the traces while leaving openings for connection points.

8. Surface Finishing: Exposed copper pads are coated with finishes like gold, nickel, or solder to prevent oxidation and improve solderability.

9. Component Assembly : If required, components are mounted onto the FPC using soldering, conductive adhesives, or surface-mount technology.

10. Testing and Inspection: The FPC undergoes electrical testing and visual inspection to ensure functionality and quality.

11. Final Processing: The FPC may be folded, shaped, or integrated into assemblies, depending on the application.

This process can vary slightly depending on the complexity (single-layer, double-layer, or multilayer FPCs) and specific requirements, but it generally follows these steps. Advanced techniques like additive printing or laser direct structuring may be used for specialized FPCs.

More info visit:www.jcftechnology.com

'