Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

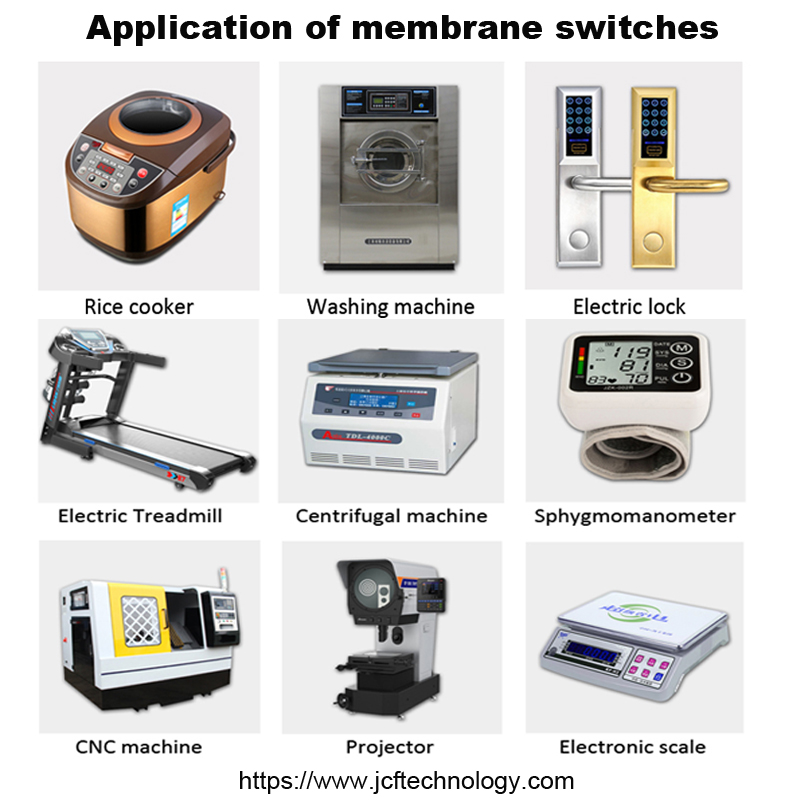

The unique structure and working principle of membrane switches allow them to effectively implement control panel functions in mechanical equipment. The following explains how membrane switches are used in mechanical equipment and their working principle:

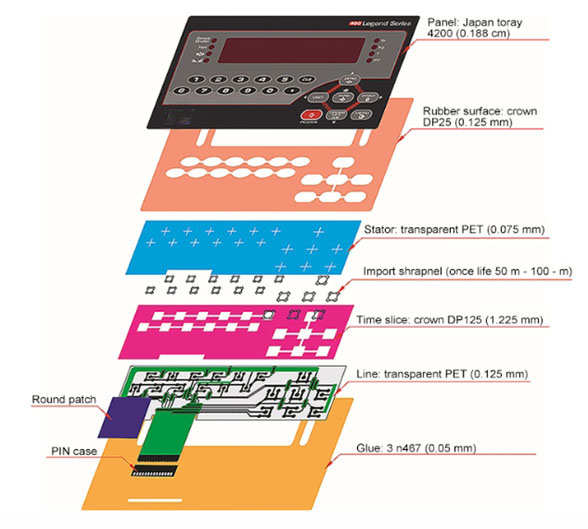

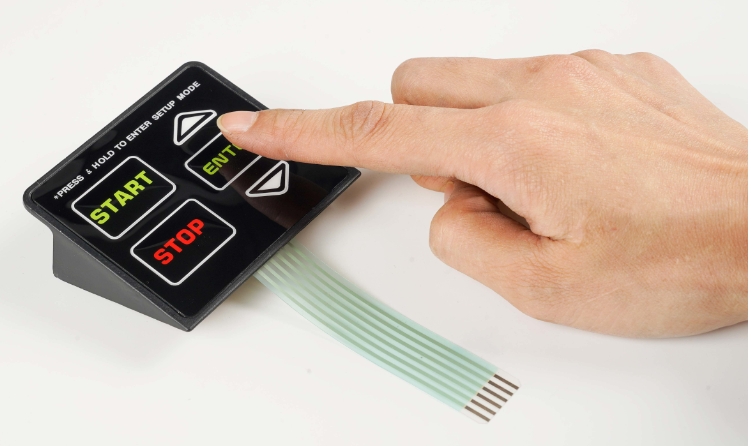

The working principle of a membrane keypad switch is based on the contact between two thin films to control the conductivity of the circuit. One is the upper circuit film, and the other is the lower circuit film. Different circuit patterns are printed on the circuit films to control the conductivity. When the user presses the circuit film with their finger, the conductive film is pressed, making contact between the two films and completing the circuit. When the pressure is released, the conductive film springs back, breaking the circuit. This method allows membrane switches to function as a fast-responding and highly sensitive touch switch, widely used in various mechanical equipment.

When using membrane switches in mechanical equipment, certain steps must be followed to ensure proper operation:

Installation: Ensure the membrane switch is securely installed and the connection to the mechanical equipment is correct.

Operation: Turn on the power of the mechanical equipment and perform the corresponding operation by pressing different areas of the membrane switch.

Monitoring: During operation, observe the status of the mechanical equipment to ensure the membrane switch responds correctly to the button presses.

To ensure the long-term stable operation of membrane panel switches in mechanical equipment, the following maintenance points should be noted:

Cleaning: Regularly clean the membrane switch to prevent dust and dirt from affecting its performance.

Moisture protection: Avoid exposing the membrane switch to a humid environment for extended periods to prevent short circuits or corrosion.

Inspection: Regularly check the connections of the membrane switch to ensure they are not loose or damaged, maintaining good electrical contact.

More info visit:www.jcftechnology.com

Email address:jcf@jcftechnology.com