Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

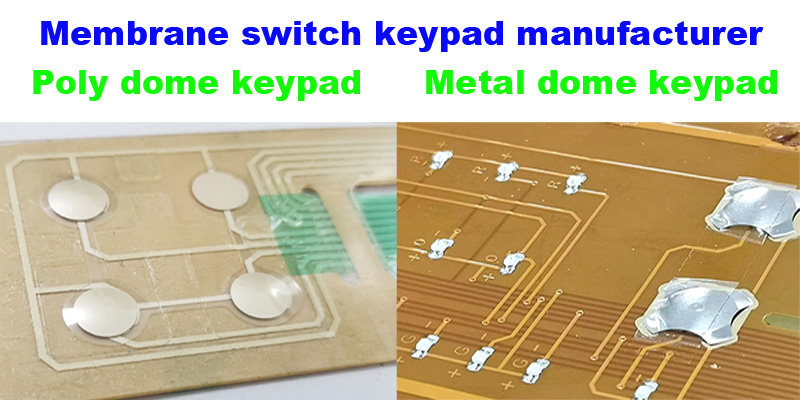

Membrane switch keypads 2 contact types

1. Metal dome

In the membrane switch, the upper circuit layer is connected to the lower circuit layer by pressing to realize the switch contact function. It is made of ultra-thin stainless steel material (0.05mm-0.1mm thickness), stamped through 5~7 processes such as mold (ultra-cryogenic processing) optical grinding processing. It is flexible and can be pressed more than one million times. It is mainly used for membrane keypads. It has four advantages: strong conductivity, stable rebound, good hand feeling, and long life time.

The role of the metal dome: 1. With the help of metal conductivity, the two-pole contacts of the switch are turned on. 2. With the help of the rebound of the shrapnel, tactile feedback is provided to the operator.

According to the shape, there are circles, triangles and squares. What JCF Technology uses is a stainless steel square metal dome, and the available specifications are 8.4mm, 10mm, 12mm, 14mm, 16mm. The choice of metal dome should be large rather than small. Try to use larger shrapnel, of course, at the same time combined with the actual product use, choose the right size. Generally, the size of 10-12mm shrapnel is recommended, which is more suitable for actual finger pressing.

2. Upper circuit silver paste embossing(Poly dome)

Another type of membrane switch keypad, through the "embossing" process, the silver paste disc of the button on the circuit is pressed into a predetermined spherical crown with a mold, so that it has a guiding effect on the button position of the entire switch.

At the same time, because the material is embossed and deformed to produce a certain degree of elasticity, the button will rebound after being pressed, so that there is a good button touch, so that people can clearly feel the switch closure. Also by pressing, contact with the lower circuit to realize the circuit conduction. Silver paste embossing requires the use of molds, especially for batch orders, and special embossing molds need to be customized, which can greatly improve production efficiency and product quality stability. The size of silver paste embossing can be designed with a diameter of 5mm-11mm, and a size of 8-10mm is recommended. The size of the button will be more suitable for finger pressing.