Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

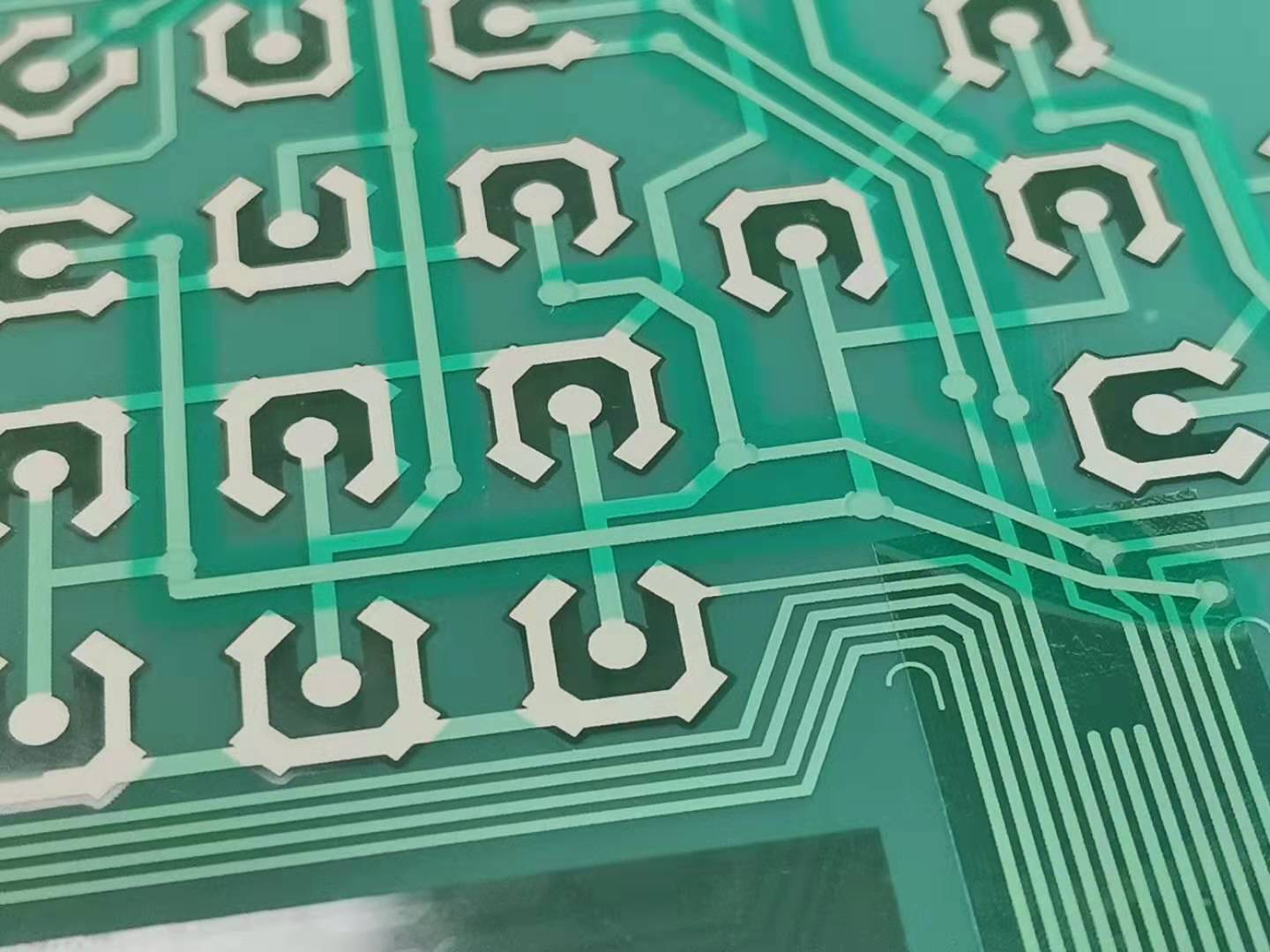

The conductive layer is screen-printed with conductive printing material, usually silver ink and carbon ink are screen-printed on the surface of the film circuit. Conductive inks commonly used in membrane switch circuits are:

1. Silver ink: American Acheson ink is specially used for conductive silver ED427SS and ED478SS for membrane switches. Their resistance values are less than 0.1Ω and 0.025Ω respectively. They are used to prevent the discoloration of silver ink and improve the wear resistance of the printed layer. ED427SS can be mixed with ED423SS arbitrarily.

2. Carbon ink: ED4233SS and ED725A are specially used on membrane switches, and their resistance values are respectively <50Ω and <0.017Ω. Conductive ink characteristics:

3. Pre-press and post-press process requirements for silk screen silver and carbon ink:

A. Before the screen printing of silver and carbon ink, it is required to fully stir after opening the lid, and stir up and down, otherwise the resistance value and electrical conductivity of the imprint will be different in the same pot of silver ink at different screen printing stages, which may sometimes be affected Adhesion to the film.

B. After the correct screen printing operation, the silver carbon ink must be stopped on the film for a while, so that the solvent wets the sheet before putting it in the oven, and drying as required to ensure the adhesion to the film.

C. In order to accurately achieve the conductivity of the silk screen silver ink, after printing, it is generally divided into three levels of drying, namely low temperature, medium temperature, and specified temperature, and it must be dry. If the resistance deviates from the requirement, it needs to be dried again until the square resistance reaches the silver Ink design requirements.

D, the resistance value should be measured according to the resistance value Ω, because the line end resistance value does not take the width and thickness of the printed line into consideration, so the line resistance value is not the standard resistance value of silver and carbon ink.

E. The silver ink printed on the screen cannot be returned to the original can. It should be poured into the clean can and used first next time to ensure the service life of the silver ink in the original can.

F, silk screen silver, carbon ink, due to their characteristics, you should choose a softer squeegee, thick film layer, thick screen, large openings, and smooth edges when screen printing. Implement the printing principle of light scraping and heavy re-inking.

4. Selection of insulating ink and main technical indicators: As the insulating ink used for the protection of the lead wire of the membrane switch, the insulating ink that matches the conductive ink and the film sheet should be selected first, which is very helpful to their adhesion , In the membrane switch, the ED-452SSUV light-curing ink of Echison is often used, the color is transparent blue or colorless, and its insulation is 2400VAC/MIL. The technical parameters of the insulating ink are:

A, stir well before use

B. According to the required insulation performance, select the mesh size of the screen to be 160-300.

C, light curing energy is controlled at 300-600MI/CM2

D, silk screen ED452SS needs 3-5 minutes for UV curing, which is conducive to achieving better quality results.

The above is only a description of the materials used in the production process of membrane switch circuits, screen printing technology and other major aspects. In fact, in the production of membrane switches, there will be problems such as static elimination on the sheet and color changes of decorative inks. Problems, the screen printing location, the screen printing environment, and purification problems will affect the quality of screen printing. Therefore, it is necessary to correctly adjust and match the five screen printing variables in the whole process of screen printing, the selection of ink characteristics, the hardness of the squeegee, the control of the squeegee angle and the setting of the squeegee speed etc, which will surely producetion excellent results Membrane switch keypad products.