Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

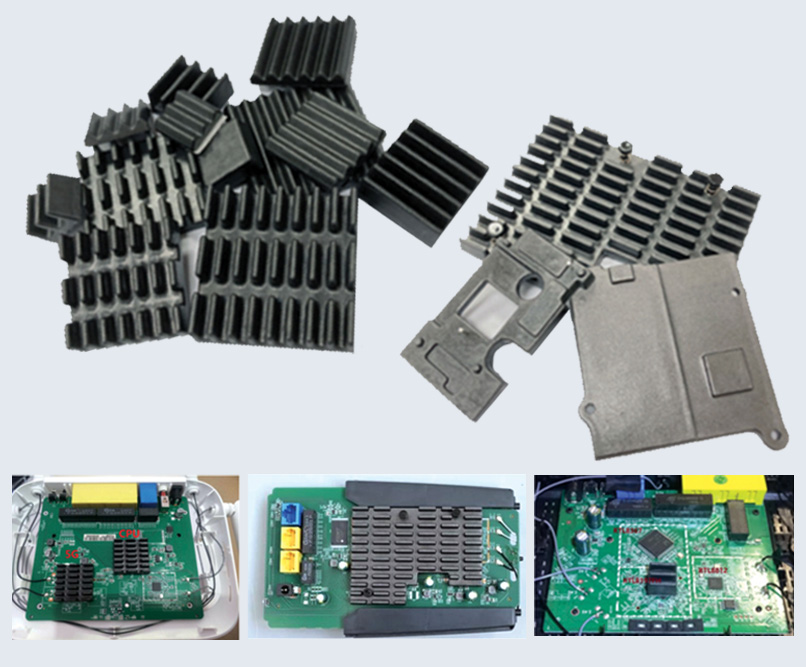

At present, most thermal conductive and heat dissipation materials are metal materials. Polymer is a new type of non-metallic thermal conductive material. When used on radiators, it has similar functions to ceramic materials and metal heat dissipation effects. It is also easy to manufacture complex structural shapes and is more suitable for customer customization needs.

Polymer thermally conductive composite materials are usually used in the fields of network communications, lighting, vehicles and smart TVs. Their main function is to have good effects in heat dissipation of components and response to electromagnetic interference. Provide heat dissipation applications in electronic structural engineering, which can improve product development and mass production more efficiently.

Compared with other heat sink, polymer heat sink have the following advantages:

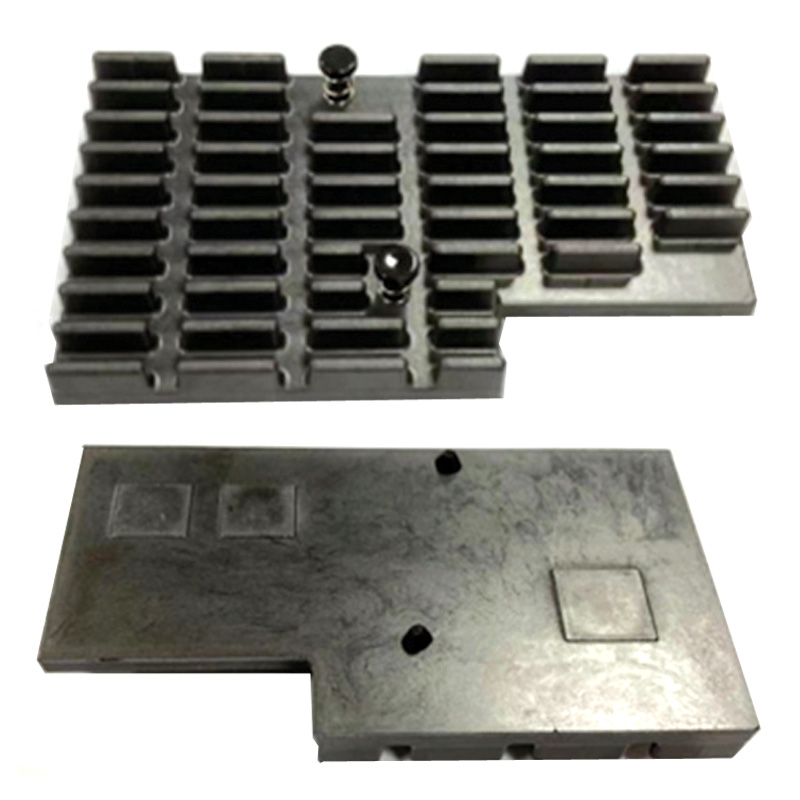

Characteristics of polymeric polymer radiators:

1. Material: non-metal, light weight (density 1.8), high radiation coefficient (less than 0.8), high thermal conductivity (K5-40), high temperature resistance, UV resistance, and waterproof.

Certification report of polymer heat sink:

Future development trends of polymer heat sink:

With the development of science and technology and the improvement of environmental protection requirements, the application of polymer heat sink will become more and more widespread. Future development trends are mainly reflected in the following aspects:

1. Higher heat dissipation efficiency: By optimizing design and improving materials, the heat dissipation efficiency of polymer heat sink is improved.

2. Wider application fields: With the development of new materials and new technologies, polymer heat sink will be used in more fields.