Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

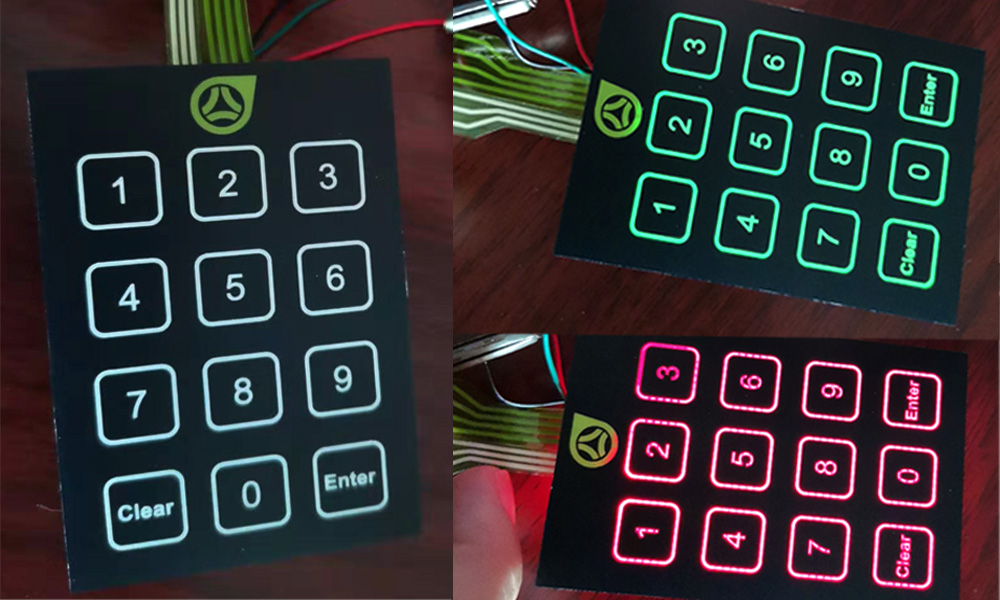

One of the ways to enhance the user experience and differentiate your equipment from the competition is to incorporate backlighting into the membrane switch design. Backlighting involves strategically placing lights into the membrane switch construction to make keypads, legends, and displays easier to read. There are specific cosmetic and cost advantages and disadvantages to be considered, based on the backlighting method employed.

Light Emitting Diodes (LEDs):

LEDs are used primarily as indicator lights, and are a popular, low-cost, point-source lighting method. Embedded LED’s emit very little heat, and come in a variety of colors including red, yellow, green, blue, white, and bi-color lamp packages.Various intensities are available, some of which are especially designed for viewing in outdoor environments.

Surface mount LEDs can be bonded into our polyester switch constructions, which provide a reliable, cost effective light source.

An even greater variety of lamp packages can be used in PCB Membrane Switches and Copper Flex Membrane Switches, and can be through-hole soldered, which enhances durability.

Other features of LED backlighting include:

Reliability and long life – typically more than 100,000 hours

Low cost

Efficient power consumption, operating on low voltages

Available in a wide variety of colors, intensities, and lamp packages

Electroluminescent (EL) Lighting

EL lamps contain phosphors, which convert electrical energy directly into light energy. The high efficiency of this conversion minimizes power consumption and losses due to heat or IR emissions. EL backlighting devices consequently consume relatively little power under normal operation. They are best suited for low and no light applications where the backlight is not always on, because the phosphors tend to decay with extended use at high voltages and frequencies. The useful life of an EL lamp will vary depending on the quality of the phosphors and how hard the lamp is being driven.

Some additional features and design considerations for EL lamps are:

EL lamps consume very little power

Provides uniform, balanced backlighting of the entire membrane switch area

Requires a DC to AC inverter to operate

Thin profile and durability make it suitable for most membrane switch constructions

Limited color options are available.

Membrane switch Technical Datas:

1 Electrical Performance

(1) Operating Voltage: ≤50VD

(2) Operating Current: ≤100mA

(3) Contact Resistance: 0.5~10Ω

(4) Insulation Resistance: ≥100MΩ(100VDC)

(5) Base Material Withstand: 2kDVC

(6) Contact bounce: ≤6ms

(7) Loop Resistance: 50Ω,150Ω,350Ω or as per clients’ requirement

2 Mechanical Properties

(1) Life expectancy: >1 million times

(2) Switch stroke: 0.1-0.4mm(Flat type)0.4-1.0mm(Tactile type)

(3) Actuation force: 15~750g

(4) Flex Tail Pitch(Standard): 2.54 /2.50 /1.27/ 1.25mm

3 Environment Specification

(1) Operation Temperature: -20°C~+70°C

(2) Storage temperature: -40°C~+85°C

(3) Humidity: 40 C, 90%-95%, 240 hours

4 Printing Indicator

(1) Size Deviation: ±0.15mm

(2) Side Boundary: ≤0.1mm

Basic Properties .

|

Electrical Properties: |

|

|

Rated Voltage |

≤50V DC |

|

Rated Current |

≤ 100mA |

|

Operating Power |

≤1W |

|

Insulation Resistance |

≥100MΩ (250V DC) |

|

Loop Resistance |

10Ω~2kΩ (based on the design) |

|

Contact Resistance |

0.5 ~ 5Ω |

|

Wire Lead Resistance |

<1Ω/cm |

|

Base Material Voltage Withstand |

1500V DC |

|

Mechanical Properties: |

|

|

Life Expectancy |

Flat type ≥ 5 million times, Tactile type ≥ 1 million times |

|

Operation Force |

Flat Type 57-284g ,Tactile Type 170-397g |

|

Dome Rebound Time |

≤6ms |

|

Tail Bending Performance |

≤180° |

|

Switch Stroke |

Flat 0.1~0.5mm,Tactile 0.6~1.5mm |

|

Vibration |

20G's max. |

|

Thickness |

0.7~1.5 mm |

|

Environmental Properties: |

|

|

Operation Temperature |

-40°C to +80°C (-40°to 176°F) |

|

Storage Temperature |

-40°C to +85°C (-40°to 185°F) |

|

Atmospheric Pressure |

86 ~ 106 kPa |

|

Humidity |

+40°C, 90%~95%RH for 240 Hours |

Contact us:

Email:jcf@jcftechnology.com

Phone:+8613715205860(Wechat)