Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

Tel: +86755-27523807 +8613715205860(wechat/whatsapp)

Tel: +86755-27523807 +8613715205860(wechat/whatsapp) Email: jcf@jcftechnology.com

Email: jcf@jcftechnology.com

PCB (or printed circuit board), is typically made of copper-clad cloth or fiber infused into a resin material. The cloth/fiber used, along with the resin material, creates a cloth-to-resin ratio to determine the laminate’s type designation (FR-4, CEM-1, G-10, etc.). FR-4 is the most common material used today.

An acid-resistant solder mask is applied to the copper-clad PCB, and the exposed areas (not covered by the solder mask) are etched away using acid. The exposed copper pathways are plated with various metals to protect the copper from corrosion. Gold plating is often required on many PCBs in critical applications where corrosion and exposure to chemicals is an issue.

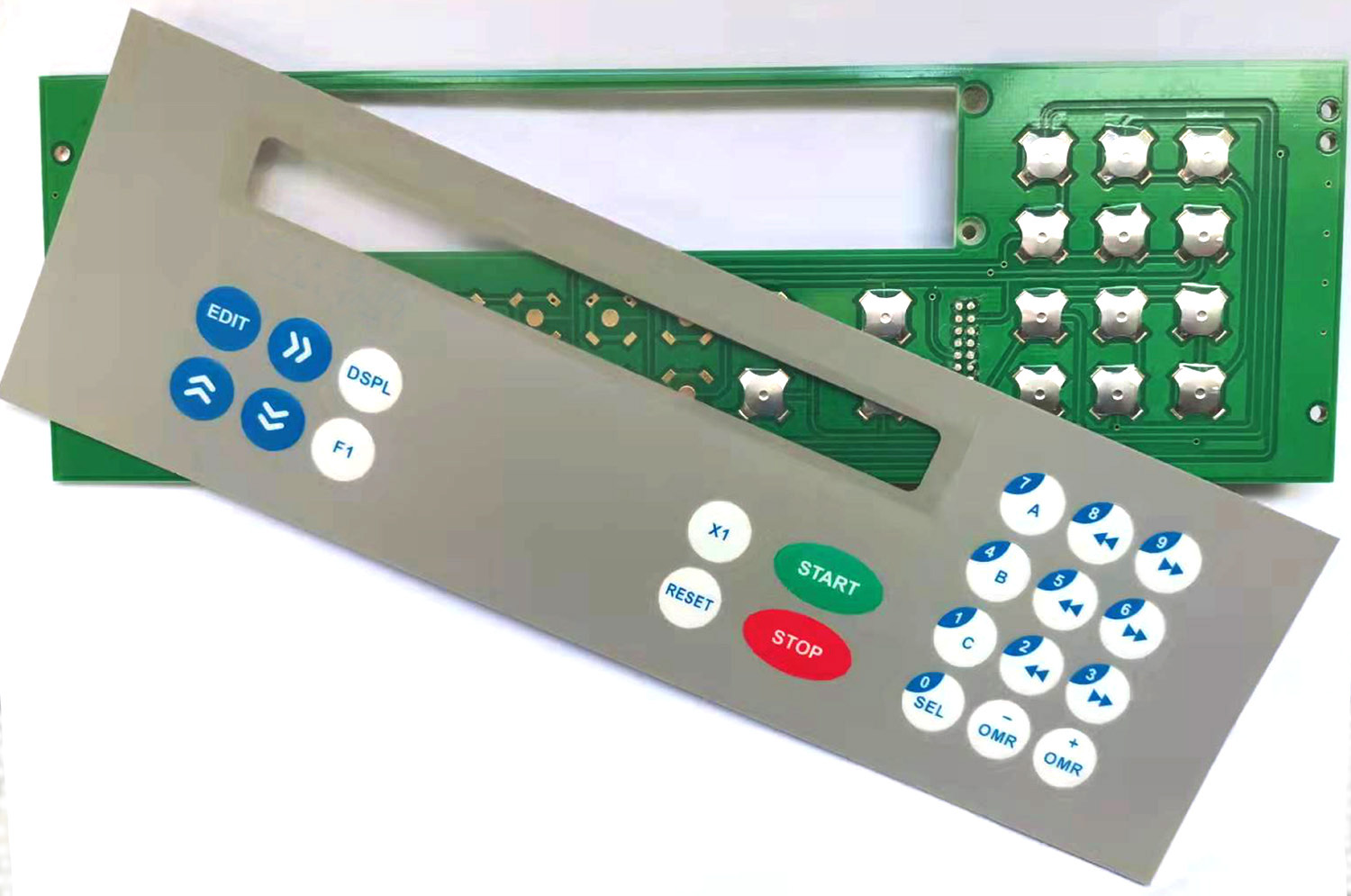

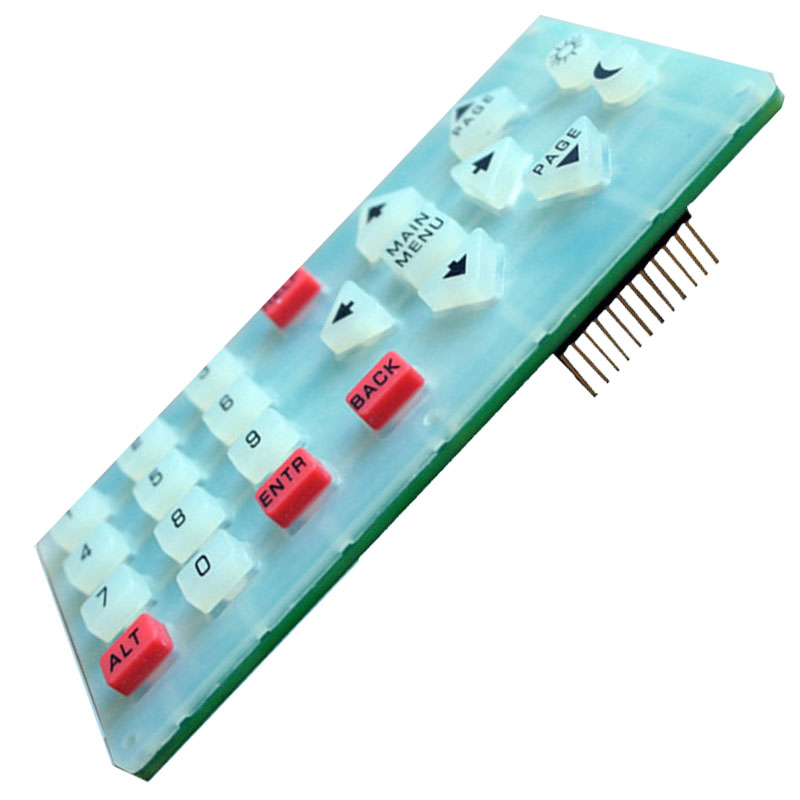

The PCB Membrane Switch construction utilizes a PCB (as described above) as the main structure/support substrate, with the membrane switch on the front of the PCB assembly, and the display (along with the other discrete components) on the back side of the PCB.

The variety of discrete components can include, but is not limited to LEDs, resistors, connectors (both SMT and though-hole), LCD and LED displays, sensors, and speakers. The addition of a daughter board can add even more design flexibility and can connect directly to the PCB membrane switch.

Although PCB Membrane Switches are generally more costly than Silver Flex Membrane Switches, they enjoy several advantages over Silver Flex switches:

Lower electrical resistance/higher conductivity.

Hard soldering components on a PCB is a more robust method to attach components vs. epoxy silver paste.

Soldering many component types using automated pick-and-place equipment.

Ideal for smaller designs where dense circuit patterns or trace routing limitations exist, by using plated thru-hole technology to utilize both sides of the PCB.Plating options such as gold, tin-lead, and nickel.Can be used in extreme environments, and high reliability/high-vibration environments.

PCB Membrane Switch Design Options & Considerations:

Single-sided, double-sided, and multi-layer designs available Tight trace routing capabilities Plating options can be tin-lead,nickel, or gold Tactile and non-tactile with either metal or polyester tactile domes Pillow or rim-embossed graphic overlays LEDs and other components can be soldered and are more robust Graphic overlays that can be digitally printed, screen printed, or a combination of both The graphic overlays can incorporate transparent and tinted display windows,as well as selective textures and UV hardcoat surface finishes.

Membrane switch Technical Datas:

1 Electrical Performance

(1) Operating Voltage: ≤50VD

(2) Operating Current: ≤100mA

(3) Contact Resistance: 0.5~10Ω

(4) Insulation Resistance: ≥100MΩ(100VDC)

(5) Base Material Withstand: 2kDVC

(6) Contact bounce: ≤6ms

(7) Loop Resistance: 50Ω,150Ω,350Ω or as per clients’ requirement

2 Mechanical Properties

(1) Life expectancy: >1 million times

(2) Switch stroke: 0.1-0.4mm(Flat type)0.4-1.0mm(Tactile type)

(3) Actuation force: 15~750g

(4) Flex Tail Pitch(Standard): 2.54 /2.50 /1.27/ 1.25mm

3 Environment Specification

(1) Operation Temperature: -20°C~+70°C

(2) Storage temperature: -40°C~+85°C

(3) Humidity: 40 C, 90%-95%, 240 hours

4 Printing Indicator

(1) Size Deviation: ±0.15mm

(2) Side Boundary: ≤0.1mm

Basic Properties .

|

Electrical Properties: |

|

|

Rated Voltage |

≤50V DC |

|

Rated Current |

≤ 100mA |

|

Operating Power |

≤1W |

|

Insulation Resistance |

≥100MΩ (250V DC) |

|

Loop Resistance |

10Ω~2kΩ (based on the design) |

|

Contact Resistance |

0.5 ~ 5Ω |

|

Wire Lead Resistance |

<1Ω/cm |

|

Base Material Voltage Withstand |

1500V DC |

|

Mechanical Properties: |

|

|

Life Expectancy |

Flat type ≥ 5 million times, Tactile type ≥ 1 million times |

|

Operation Force |

Flat Type 57-284g ,Tactile Type 170-397g |

|

Dome Rebound Time |

≤6ms |

|

Tail Bending Performance |

≤180° |

|

Switch Stroke |

Flat 0.1~0.5mm,Tactile 0.6~1.5mm |

|

Vibration |

20G's max. |

|

Thickness |

0.7~1.5 mm |

|

Environmental Properties: |

|

|

Operation Temperature |

-40°C to +80°C (-40°to 176°F) |

|

Storage Temperature |

-40°C to +85°C (-40°to 185°F) |

|

Atmospheric Pressure |

86 ~ 106 kPa |

|

Humidity |

+40°C, 90%~95%RH for 240 Hours |

Contact us:

Email:jcf@jcftechnology.com

Phone:+8613715205860(Wechat)